SPONSORED: Extensive, years-long PV field studies by DuPont in the examination of solar defects have yielded valuable knowledge of the areas where solar panels can fail and of the most common defects found.

This accumulation of knowledge enables the development of more stringent risk mitigation techniques and helps purchasers of solar power systems to make educated and informed materials assessments.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

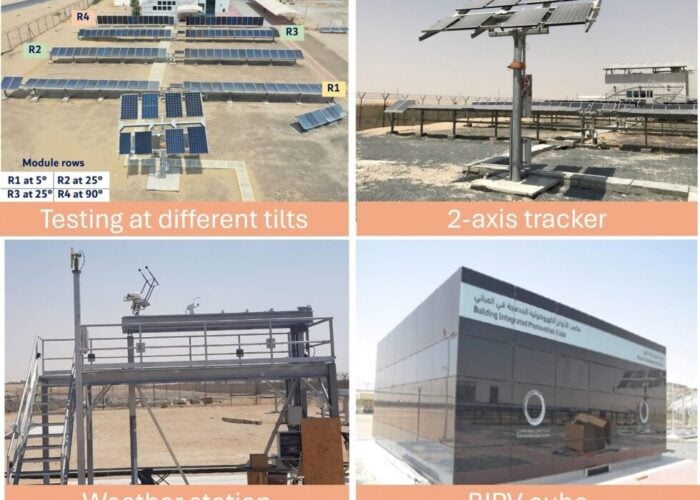

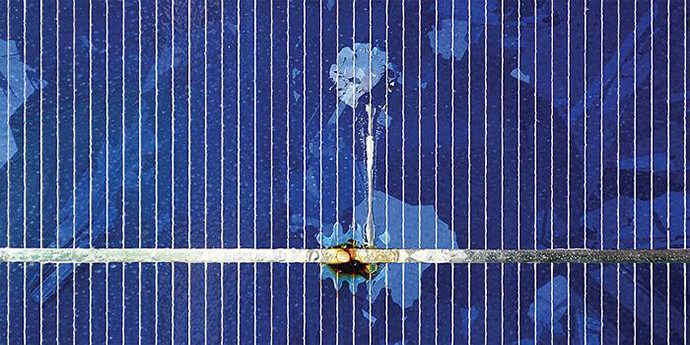

For this study, module defects were identified via visual inspection combined with the use of a thermal camera. A PV module with a defect might not have a safety issue or power loss, but may differ in some way from a perfect module. In many instances, the defects were not uniform across all modules in a particular installation.

One area that was examined in the study involved the use of alternative backsheet materials that were lacking in-depth, long-term performance testing. This lack of performance data resulted in expensive field failures. The study highlighted the critical role that backsheets play in the performance of solar modules. Due to little standardization between polyethylene terephthalate (PET) films, inconsistent performance in the field and a high rate of early field failures, such as yellowing and cracking, were found. Cracked and damaged backsheets can cause electrical insulation failure, posing a safety hazard and putting your panels at risk.

Drawing on decades of experience researching, manufacturing and testing solar materials, DuPont offers best practices for solar array design, component selection and long-term maintenance. DuPont has made these available as a free-of-charge resource to interested EPCs, rooftop installers and energy solutions providers.

To access this free resource click here.

This article was written by DuPont.