Today, the entire PV sector is looking at cell production technologies. From polysilicon producers (needing to understand silicon purity levels) to site investors (having to forecast site returns), the question of p-type or n-type component production and supply has equal significance.

There are many voices claiming to know how the p-type versus n-type question will be resolved in the coming years. Mostly, the outlooks tend to support company strategies and investment decisions, as would be expected. This just serves to emphasise how complex the issue is today.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

During the past few years, we have focused our flagship PV CellTech conferences towards answering the question of: when does n-type go mainstream, and what n-type variants will prevail? While also looking closely at how p-type (specifically modifications of the current mainstream PERC concept) can keep its efficiency growth moving in the right direction. We have heard many perspectives on these topics in the past few years.

During the recent PV CellTech 2021 Online conference, the opening keynote presentation was delivered by Professor Martin Green of the University of New South Wales (UNSW). The scope of the talk was to explain the efficiency limits from PERC, TOPCon, HJT and IBC cell types.

The presentation was the clear highlight of PV Celltech 2021 Online. The content addressed all the questions raised above, in particular how p-type can evolve going forward. For anyone wanting to understand the basic differences in the cell concepts being promoted in manufacturing today, and what their inherent limits are, this presentation has truly must-attend status attached.

After PV CellTech, we agreed with Professor Green that we could rerun the recording of the talk, to make it accessible to a wider global audience. This takes place on 6 October 2021, with two times (zones) available to choose from.

To access the presentation, please visit the registration page here. You can toggle between the two times using the drop-down option in the upper middle of this registration link.

Update on p-type vs n-type production in 2021

Before listening to the talk next week, it is worthwhile looking at what the PV manufacturing landscape is this year, in particular how much is coming from p-type and n-type variants.

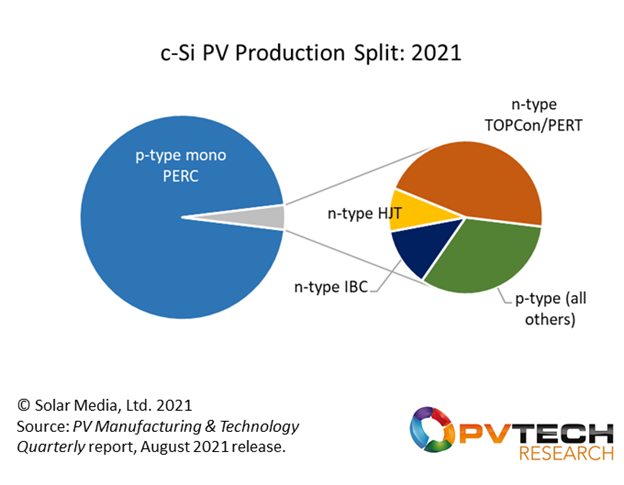

The graphic below is taken from the most recent release of PV Tech’s PV Manufacturing & Technology Quarterly report.

p-mono PERC dominates c-Si manufacturing in 2021, with growth across n-type variants expected to increase in the next 3-5 years.

This graphic shows clearly how much p-type mono PERC dominates production levels currently. Production output from the challenging n-type variants is typically dominated by two to three companies in each of the segments shown for n-type. The p-type (all others) refers to legacy p-type multi production or p-type mono (using Al-BSF process flows).

Understanding how this split is set to change in 2022 underpins the questions asked at the start of this article, and hopefully sets the scene perfectly for the presentation rerun next week from Professor Green!