Italian solar manufacturer 3Sun and French research firm CEA (Commissariat à l’énergie atomique in French) have achieved a 30.8% solar cell efficiency on tandem perovskite silicon solar cell technology.

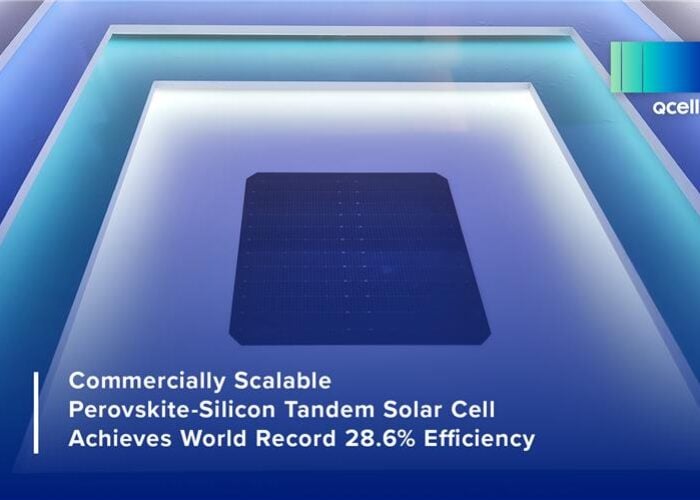

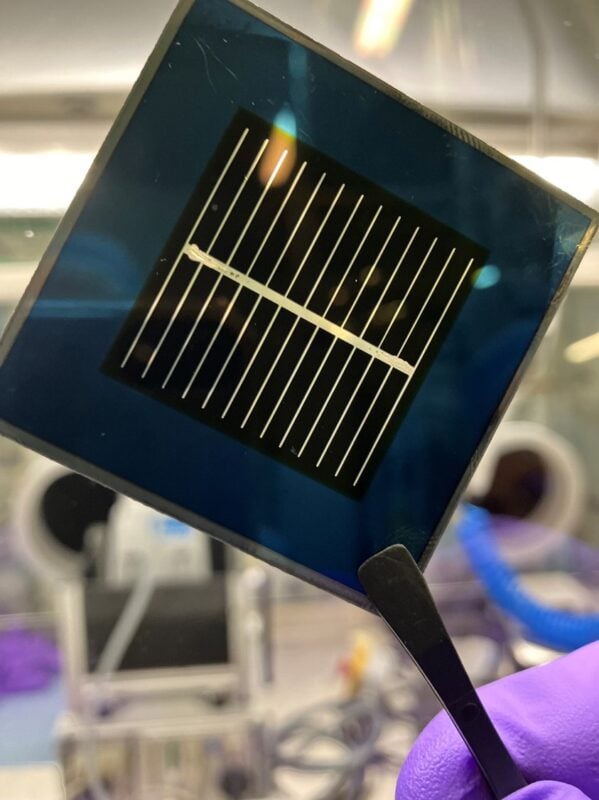

The new record was achieved on a 9cm2 solar cell, which the companies said should allow for an easier transition towards industrial-scale manufacturing, compared to most previous records, which were achieved on 1cm2 cells.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

The CEA said the efficiency record was certified by Italian independent organisation JRC-ESTI (The Joint Research Centre of the European Solar Test Installation).

Among the records achieved on a 1cm2 cell is one from researchers at the Fraunhofer Institute for Solar Energy Systems (ISE) which developed a perovskite silicon solar cell with a power conversion efficiency of 31.6% last September.

The 9cm2 cell was developed at CEA’s laboratories, located at the National Institute for Solar Energy. In over a year, both entities have improved the cell efficiency by 2.4% from 28.4% reached in January 2024 to 30.8% earlier this week.

“This achievement represents significant progress towards large-scale production of Tandem solar cells. Thanks to their high performance, these cells are destined to replace conventional silicon-only solar cells. In the coming years, this technology is expected to become the standard in the photovoltaic industry, overcoming the limitations of silicon cells,” said Stefano Lorenzi, head of 3SUN.

This new record surpasses the theoretical efficiency limit for conventional silicon technologies which is set at around 29% in current solar PV manufacturing plants.

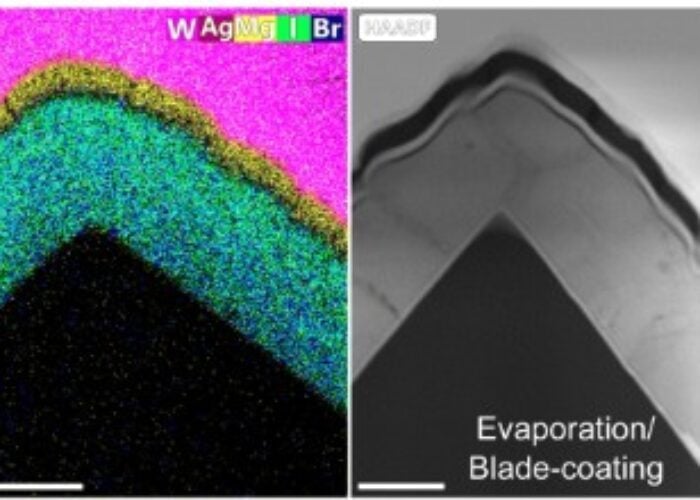

According to 3sun and CEA, the tandem perovskite-over-silicon PV cell positions itself as a credible successor to current silicon-based technologies, with the perovskite part of the tandem cell allowing for increased light capture and improving the performance potential of the technology.

A recent report from a study made by six Fraunhofer institutes identified perovskite-silicon tandem cells as the “prerequisite” for the next PV technological leap. That study was unable to find a non-toxic alternative that would not require the use of lead for perovskite compounds to produce tandem cells.

Another recent study on perovskite tandem technology, this time from the US National Renewable Energy Laboratory (NREL), highlighted solar module efficiency and nameplate production capacity as the “most significant” factors in reducing manufacturing costs for perovskite silicon tandem PV technology.

“We are regularly improving this record and proving that Asia’s domination in the photovoltaic module production sector is not inevitable. Research operators and industrialists can still be competitive in Europe,” added David Duca, head of CEA’s solar technology department.

Perovskite technology was at the centre of PV Tech Power’s latest cover issue tackling the “hopes and hypes” of the technology through several articles. Premium subscribers can access PV Tech Power 41 here.