A group of key stakeholders in the PV industry has called for measures to support a competitive domestic European upstream PV value chain.

They are urging Europe to expand its own domestic manufacturing capacity and reduce its current dependency on PV products from China, which represents more than 80% of the global upstream solar value chain and could jeopardise Europe’s deployment of solar PV in case of supply disruptions.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

The representatives included are polysilicon manufacturer Wacker, solar cell and module manufacturer Meyer Burger, silicon ingot and wafer manufacturers NorSun and Norwegian Crystals, equipment manufacturer ECM Group as well as research institutes the Fraunhofer Institute for Solar Energy Systems ISE and Fraunhofer Center for Silicon Photovoltaics CSP.

“Business risks must be mitigated to an extent stakeholders are able to invest in establishing and to competitively operate a sustainable solar upstream manufacturing value chain in Europe,” the organisations said in a statement.

To be able to play on a level field with international competition, the supporters of this call have asked for several measures to be adopted:

- Subsidies for investments in PV manufacturing and supply item production lines, as well as for respective operational expenses of new and existing capacities

- Warranties for a competitive energy price – in the order of €40/MWh (US$43/MWh) – especially for energy-intensive process steps of the solar manufacturing value chain

- Low interest-rate loans and credit guarantees

- Local content schemes

- Tax-related to CO2 (eq) emissions in product manufacturing and faster deployment of renewables to decarbonise the energy generation

Domestic PV manufacturing capacity could be revitalised with public support in the order of €0.10-0.15/Wp (US$0.10-0.16/Wp) of produced PV, spent over the next decade to support the installation and operation of PV manufacturing facilities, the stakeholders said in a joint statement.

The quantity proposed for European manufacturers is slightly lower than the incentives included in the US’s Inflation Reduction Act (IRA).

“We need the right policy framework and more financial support mechanisms for making investments into PV value chain more attractive in Europe, especially for capex and energy-intensive upstream manufacturing such as ingot and wafer production,” said Carsten Rohr, chief commercial officer at NorSun.

The scale of the European PV manufacturing industry needs to significantly increase from today’s capacity to “mitigate vulnerability against supply chain disruptions and to ensure the success of EU energy transition”, says the statement, which can be read here.

The European stakeholders discussed last October the establishment of a 20-30GW wafer manufacturing capacity in Europe in the short term, with the key issue being the high cost to build up and operate such facilities, as Europe is currently facing an energy crisis with high prices of electricity.

The stakeholders have estimated the capex per 10GWp of new polysilicon and wafer factories could reach €3-4 billion, with a lead-up time of three years and payback times of four years or more. The implementation of several dozen gigawatts of wafer production capacity in Europe in the next five years could be achieved, according to the statement.

“We are convinced that a sustainable European PV manufacturing industry can be revitalised with governmental support to promote the installation and operation of PV manufacturing facilities,” said Andreas Bett, director of Fraunhofer ISE.

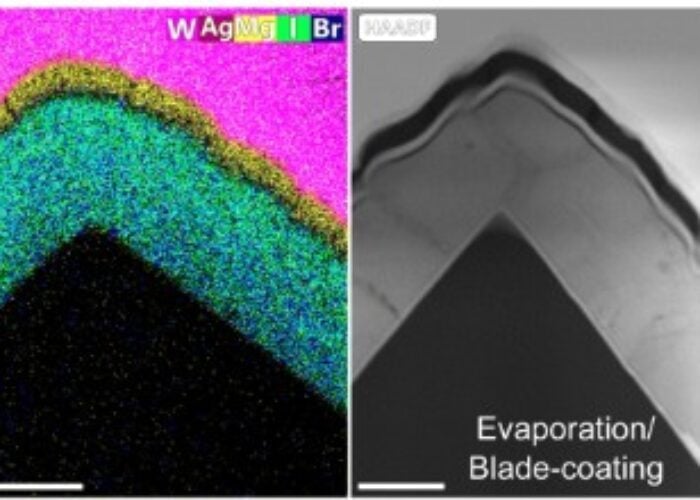

Moreover, the key stakeholders are calling for crystalline silicon to become the predominant technology for solar PV in Europe.

This is the latest call from key European solar companies demanding that the EU support the development of domestic European PV manufacturing capacity capable of competing with China’s dominance and in line with the US’s IRA.

Spearheaded by innovation group EIT InnoEnergy, a European Solar PV Industry Alliance was launched last December to promote investments in EU solar manufacturing and a target of 30GW of manufacturing capacity by 2025.