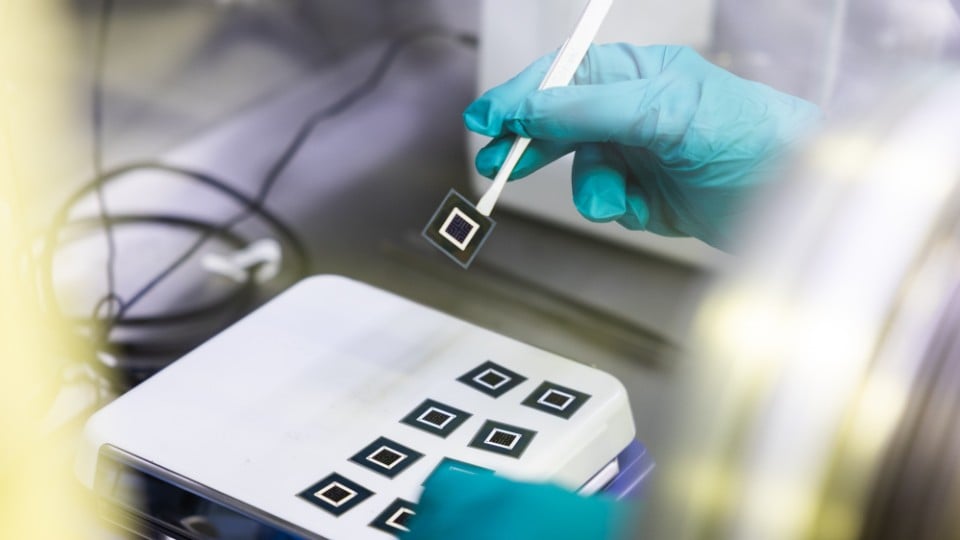

Scientists from Germany and Saudi Arabia have discovered that perovskite thin-film cells are compatible with current industry standard silicon solar cells, which they claim is a “crucial step toward the industrialisation of perovskite silicon tandem solar cells”.

Research from the Fraunhofer Institute for Solar Energy Systems (ISE), Freiburg University and the King Abdullah University of Science and Technology (KAUST) published yesterday shows that the passivation of a perovskite top cell is possible in combination with industry standard silicon bottom cells.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

Passivation is a technique used to reduce electron recombination in solar cells. It encourages more electrons to produce power rather than recombining with the cell surface, reducing power loss and increasing efficiency.

Perovskite-silicon tandem solar cells are generally constructed with a perovskite top layer and a silicon bottom layer, which collectively allow the cell to absorb a broader range of the light spectrum and convert it into power. There are different combinations and configurations of these two layers, but the general principle holds through most efforts to produce tandem products.

In an announcement, the researchers said that using industry standard silicon cells would be advantageous “for large-scale production of these tandem solar cells”, as the production process is well established.

However, the researchers added that industry standard silicon cells “are textured to increase their surface area, enhancing efficiency, but this texturisation also complicates the deposition of the perovskite layer.”

The new discovery shows that perovskite layers can be passivated on top of textured silicon cells. The resulting cell has an efficiency of 33.1%, with an open-circuit voltage of 2.01V.

‘A solid foundation for all future research’

Oussama Er-Raji, the lead author of the paper and a scientist at Fraunhofer ISE, said, “Prior success [was] largely confined to flat-front architectures. But we have now managed excellent passivation by depositing 1,3-diaminopropane dihydroiodide on the uneven perovskite surface.”

Additionally, the scientists found that passivating the perovskite layer “improved the conductivity and thus the fill factor of the cell”, because passivation affects the entire perovskite layer, unlike processes involving silicon cells, where surface treatment only affects the upper layers. This improves cell efficiency.

“This realisation provides a solid foundation for all future research in this area,” said Stefaan De Wolf, professor of materials science and engineering and applied physics at KAUST. “It enhances our understanding of the processes occurring in the top cell while converting light into electricity, enabling scientists to leverage this knowledge to develop better tandem solar cells.”

Stefan Glunz, professor of photovoltaic energy conversion at the University of Freiburg and director of the Photovoltaics Division at Fraunhofer ISE, added: “Surface passivation of solar cells is not just a nice-to-have feature; it is an essential booster for their efficiency and stability.

“For today’s silicon solar cells, surface passivation was the key for high efficiencies in industrial production, and it is encouraging that the PV industry will benefit from these positive effects for perovskite silicon tandem solar cells as well.”

Companies and institutions worldwide are developing perovskite tandem cell offerings with increasing efficiencies. Earlier this week, Chinese solar manufacturer Huasun calimed a new record for a laboratory-size cell using a tandem perovskite and heterojunction technology (HJT) silicon cell.

However, the technology has yet to reach full industrial scale. British perovskite firm Oxford PV said it shipped the first commercial tandem modules earlier this year to an unnamed US client, but challenges around the material’s volatility and manufacturing processes have prevented it from breaking the mainstream PV industry yet.

PV Tech Premium subscribers can read a deep-dive into the “hope and hype” of perovskite technology here.

PV Tech publisher Solar Media will host the third edition of PV CellTech USA on 7-8 October 2025 in San Francisco. Industry experts, including American Clean Power Association (ACP) vice president of supply chain and manufacturing MJ Shiao, will speak on topics including manufacturign processes and the US cell supply chain. Book tickets for the event at the website here.