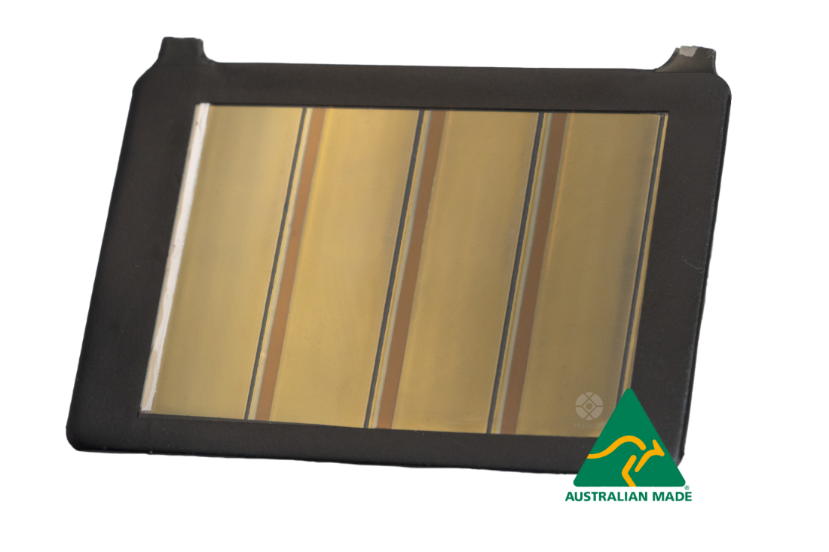

Australian PV solar cell manufacturer Halocell Energy has launched its first perovskite-based product called the Halocell Ambient Modules.

The Halocell Ambient Modules (pictured) are purpose-built for low-light conditions of 500 lux and below. Because of this, Halocell claims these are ideal for homes, offices and industrial settings.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

These will be manufactured at Halocell’s production facility in Wagga Wagga, a city in the Riverina region of New South Wales.

Another key aspect of the solar PV modules is that 98% of the functional materials can be recycled and reclaimed, creating a circular process for decommissioning. This aims to help prevent modules from entering landfills, which will likely become a growing issue, particularly in Australia, in the coming years and decades.

Discussing the modules, the company’s website said they “deliver lightweight, flexible, and highly efficient energy for indoor electronic devices. They provide continuous, reducing reliance on batteries, and are particularly beneficial for IoT devices, smart home gadgets, and other low-power electronics.”

Alongside the launch of Halocell’s first module product series, the organisation has also penned a deal with Sofab Inks to optimise its future PV modules.

Specifically, Halocell will leverage Sofab Inks’ nanoparticle inks, which are designed for charge transport layers in PV. According to the two companies, these inks are engineered to reduce costs, enhance stability, and enable industrial-scale perovskite PV manufacturing.

Sofab Inks was founded in 2022 as a spinout from the US’ University of Louisville’s Conn Center for Renewable Energy Research. The organisation recently announced a successful funding milestone of US$1.2 million.

With Sofab Inks set to supply Halocell with its nanoparticle inks, Halocell will continue to formulate and manufacture its exclusive perovskite inks for various applications.

This becomes the latest partnership Halocell Energy has signed in recent months, with deals with the University of Queensland and First Graphene.

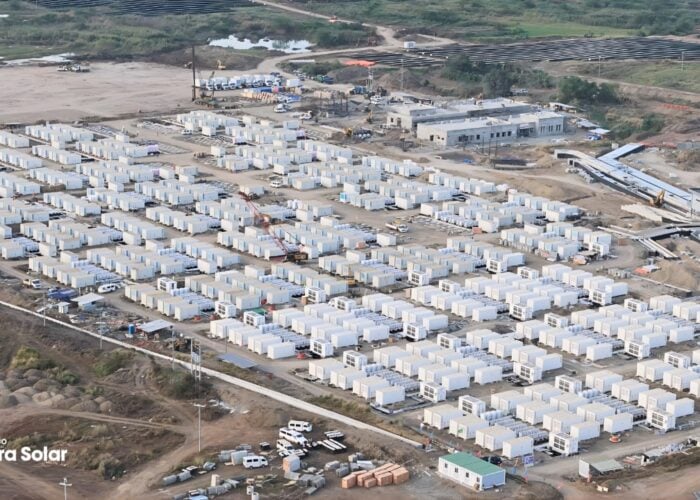

Australia’s domestic solar PV module manufacturing capabilities

Halocell is one of several Australian solar module manufacturers, another being Tindo Solar, which recently signed a 15MW module supply agreement for projects in Vietnam.

Although solar cell research and development (R&D) in Australia is among the most influential globally – particularly due to the legacy of Professor Martin Green and his team at the University of New South Wales (UNSW) and their groundbreaking work on Passivated Emitter and Rear Cell (PERC) technology in the 1980s – domestic manufacturing capabilities have somewhat lagged behind.

As such, the number of partnerships between Australian universities and major Chinese module manufacturers has risen, coupling Australian solar innovation with China’s industrial prowess. This has been witnessed via the recent collaboration between Australian PV cell technology startup SunDrive Solar and Chinese solar manufacturer Trina Solar.

Brett Hallam, an associate professor and the research director for advanced hydrogenation at the University of New South Wales (UNSW), told PV Tech Premium earlier this year that this is something that could become more numerous in Australia.

“Our best chance of establishing a viable solar industry is in partnership with China,” Hallam noted.

The Australian government has introduced several initiatives to help spur growth in domestic manufacturing. This includes the launch of the Solar ScaleUp Challenge and Solar Sunshot programme.

Launched in March 2024, Sunshot primarily focuses on how components are made, whereas the newly launched Challenge focuses on deployment. As such, the two initiatives aim to bolster Australia’s efforts to become a hub for solar innovation and development.

Richard Petterson, CEO of Tindo, told PV Tech Premium last year that the initiatives could help put Australia on the global map for manufacturing.