Perovskite-on-silicon PV modules are more environmentally advantageous than conventional silicon heterojunction (HJT) modules over a 25-year lifetime, according to a study from researchers in Germany.

Assessing perovskite-on-silicon modules across categories such as global warming potential, water consumption, toxicity and metals usage, the team studied the materials and energy input for a module’s ‘cradle to gate’ lifecycle, covering input for wafer production, manufacture of the perovskite cell and module production.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

They weighed up the environmental impact of the perovskite tandem module against the electricity generated over its lifetime. While they found the overall environmental impact of the perovskite-on-silicon tandem module to be higher than the HJT module due to additional process steps, this is offset by higher efficiencies.

“We found that the perovskite-on-silicon module has 6% to 18% less environmental impact than a silicon module when we consider the additional energy generated over the tandem module’s 25-year lifetime,” said Martin Roffeis, co-author from The Technical University of Berlin.

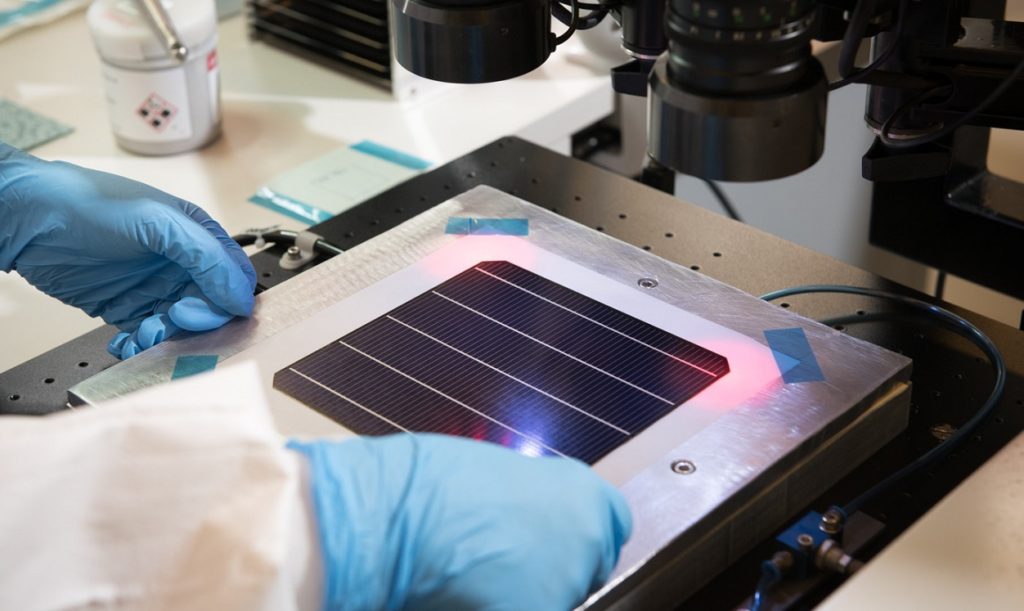

While lifecycle assessments of perovskite-on-silicon PV modules have so far relied heavily on data from laboratory and test facilities rather than manufacturers, the researchers assessed the environmental performance of industrially produced modules using data from an Oxford PV manufacturing line in Germany.

Titled ‘New insights into the environmental performance of perovskite-on-silicon tandem solar cells – a life cycle assessment of industrially manufactured modules’, the study is the first lifecycle assessment using industry primary data, according to the researchers.

Perovskite-on-silicon solar technology is based on a tandem system where a perovskite cell is deposited on top of a silicon cell, maximising power generation.

Researchers at EPFL’s Photovoltaics and Thin Film Electronics Laboratory and CSEM’s Sustainable Energy Centre last week claimed two world records for perovskite-on-silicon cells as they reached a power conversion efficiency of 31.25%.

The tandem module used in the latest study would generate the same amount of electricity in 22 years as the referenced silicon HJT module over 25 years.

“The higher power conversion efficiency of the perovskite-on-silicon tandem module compensates for its environmental impact due to the additional perovskite material and processes,” said Jan-Christoph Goldschmidt, co-author who carried out the study while at the Fraunhofer Institute for Solar Energy Systems and who is now at The Philipps University of Marburg.

Another study published earlier this month by a team at the US National Renewable Energy Laboratory (NREL) found thin-film technologies such as perovskites and cadmium telluride can markedly reduce the carbon intensity of PV compared with silicon alternatives.