Swiss PV manufacturer Meyer Burger and US-based firm Solestial have announced a “strategic partnership” to scale the manufacturing of silicon solar technology for use in space.

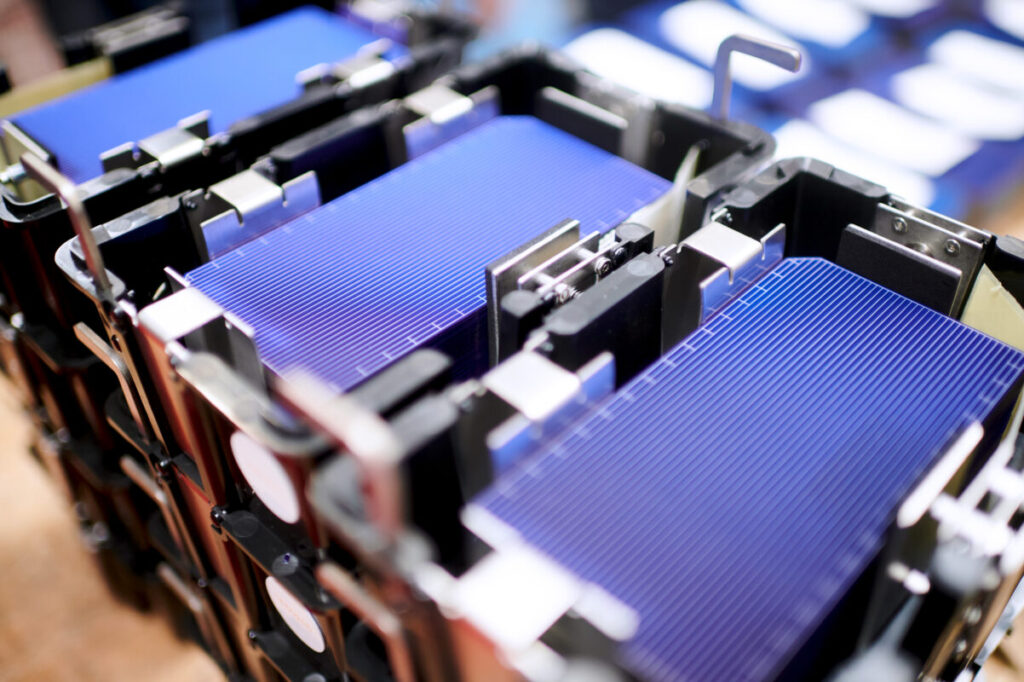

Under the agreement, Solestial will deliver its ultra-thin silicon wafers to Meyer Burger, which are notable as they can anneal damage from radiation to electrons and protons at temperatures of 65 degrees Celsius. This makes the cells particularly useful for deployment in space, where cells can be damaged by exposure to radiation. Meyer Burger will apply its silicon heterojunction (HJT) technology to the wafers.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Meyer Burger will then return the products to Solestial’s facility in Tempe, Arizona, for cell metallisation, finishing and integration into solar modules. Solestial notes that, considering that there have been a number of new innovations in perovskite technology, including an additive developed by researchers from the Chung-Ang University in Korea, the power conversion efficiency of its cells could exceed 30%, although it has not supplied further details on this target.

This joint manufacturing process is set to begin by September this year, and Meyer Burger noted that the scale of its manufacturing facilities, which boast a potential annual capacity of 1.4GW, will enable the companies to provide “enough solar modules to power hundreds of spacecrafts” by the middle of next year.

“This partnership with Meyer Burger allows Solestial to take the next step in scaling production, delivering for our customers, and meeting the ever-growing demand for reliable, cost-effective, and abundant energy in space,” said Stan Herasimenka, CEO of Solestial.

However, Meyer Burger’s manufacturing work has struggled in recent months. In January, the company closed its module assembly plant in Germany, amid industry-wide growing concerns of the non-viability of European PV manufacturing, and while the company had a potential capacity of 1.4GW in 2023, it only operated around 650GW of this capacity, due to a lack of financial benefits for European-based manufacturing. Meyer Burger CEO, Gunter Erfurt, told PV Tech Premium that the move was a “massive disappointment”.

The company has since relocated its manufacturing work to the US, opening a 600MW module assembly plant in Arizona in June, the same state in which Solestial is based, to take advantage of supportive tax credits offered by the Inflation Reduction Act (IRA).

Space-based solar power has seen increased attention in recent years, with a number of programmes looking to assess the practical and financial viability of building PV systems in space. The Space Energy Initiative, a UK-based coalition of energy and space companies, for instance, suggests that a kilometre-long solar system could have a power capacity of 2GW, and produce power at a levelized cost of electricity of just £5/MWh (US$6.34/MWh).

However, considerable research into the field is still necessary, with even the Space Energy Initiative noting that operational space-based solar systems would not be in effect until the “mid 2040s”.