SPONSORED: Quality control and efficient O&M of rooftop commercial PV installations are economic and technical challenges, but essential nonetheless. The key objective in conducting O&M is to ensure that the PV system is performing at its peak. One of the main aspects of O&M is identifying underperforming modules and repairing or replacing them. There are multiple techniques to identify modules with defects, including manually checking each module, infrared imaging, and module-level monitoring. Current scientific research has shown that module-level monitoring has the advantage of finding and quantifying failures continuously during operation.

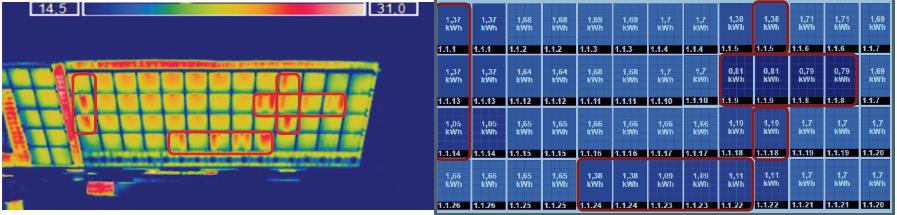

A recent research paper, Verifying defective PV-modules by IR-imaging and controlling with module optimizers[1], written in collaboration with researchers from the Bavarian Center for Applied Energy Research (ZAE Bayern) and the Materials for Electronics and Energy Technology Institute (i-MEET) compared the ability of IR-imaging and module-level monitoring in identifying and localizing defective modules. Drone-mounted infrared imaging is frequently used within the industry for quality inspection of PV systems. This technique can reveal module defects such as substring failures caused by open and short circuits, bypass- diode faults, and other defects. The goal of the study was to understand the effectiveness of this technique.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

The study tested ten rooftop PV systems installed with module-level monitoring. During the study, drone-mounted IR-imaging systems measured and recorded environmental data through IR-images of the modules. The data evaluation combined the IR readings with the cumulative production data for the entire period from module-level monitoring, along with ambient temperature, wind speed, and relative humidity from a weather data service. In addition, simulation and comparison of I-V and P-V curves of single modules, and strings with 20 modules, was performed to evaluate the electrical differences during module failure and variable operating conditions.

While the study demonstrated significant similarities between the findings delivered by IR-imaging, and the electrical data collected in the module-level monitoring, the conclusion of the study was that module-level monitoring is both more accurate and efficient. Both methods identified failures in the PV modules, but IR-imaging has limitations, as it does not account for variable effects, and temporal changes. This is because IR-imaging only offers a singular snapshot for very specific conditions without providing relevant contextual data as module-level monitoring does. The advantage of module-level monitoring is in the information that is not detected by singular imaging measurement. Module-level monitoring detects and records failures continuously during operation and provides added data regarding power and yield levels that allows O&M staff to plan the most appropriate maintenance strategy to manage these defects.

There a few key takeaways from this study that are important for the O&M industry. Module-level monitoring has the advantage over IR imaging of finding and quantifying failures continuously during operation. This is not only due to the accuracy of the findings, but also the quality of information that is provided through module-level monitoring. This information allows O&M providers to be more efficient and helps system owners have increased uptime. Just as important as the conclusion of the study is that the research paper treats module-level monitoring as the gold standard to compare all other O&M techniques. This demonstrates how O&M has evolved over the past few years and the growing role that high-resolution insight into energy production plays in the adoption and proliferation of solar energy.

[1] “Verifying defective PV-modules by IR-imaging and controlling with module optimizers”, by Claudia Buerhop, Frank W. Fecher, Tobias Pickel, Adrian Häring, Tim Adamski, Christian Camus, Jens Hauch and Christoph J. Brabec, representing the Bavarian Center for Applied Energy Research (ZAE Bayern) together with the Materials for Electronics and Energy Technology Institute (i-MEET) and SolarEdge Technologies GmbH. The study was presented to the 33rd European Photovoltaic Solar Energy Conference and Exhibition and was selected by the Executive Committee of the EU PVSEC 2017 for submission to “Progress in Photovoltaics”.