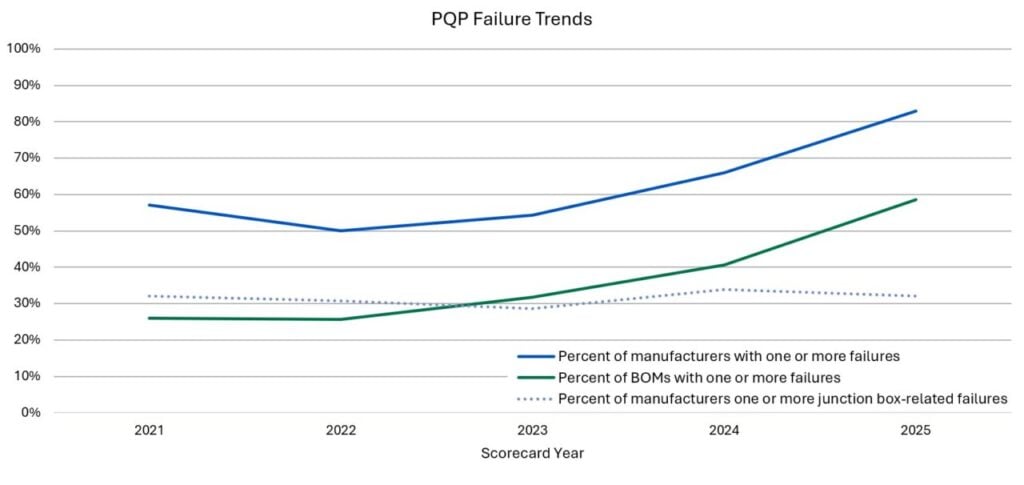

A total of 83% of module manufacturers have had at least one test failure in the Kiwa PVEL 2025 Module Reliability Scorecard, up from 66% a year ago.

Kiwa PVEL’s flagship Product Qualification Program (PQP), published today and now in its eleventh year, has seen a record growth in module test failures, despite last year’s already-record numbers.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

Tristan Erion-Lorico, vice president of sales and marketing at Kiwa PVEL, told PV Tech that “four years ago, that was at 50% and it’s steadily increased since”.

The PQP is a suite of reliability and performance tests that evaluates solar modules under different environmental and mechanical conditions. This includes effects of extreme temperatures and high humidity, mechanical stress, hail and ultraviolet light.

This year’s scorecard named 50 manufacturers as “Top Performers” in one or more tests, while nine manufacturers have been named Top Performers with at least one model type listed in each of the seven categories.

Only 21 model types have achieved Top Performer status in all seven reliability categories – which includes thermal cycling, damp heat and potential-induced degradation (PID) among others – with only three of these also being Top Performer in PAN performance. PAN files represent the production of the PV module, with Kiwa PVEL’s PAN testing analysing the module’s energy yield performance.

“The rapid pace of innovation in the PV module landscape is encouraging, and it’s great to see more products achieving Top Performer status,” said Erion-Lorico. “However, we continue to caution buyers not to assume all modules are created equal. Our testing continues to uncover significant variability in performance and long-term reliability. The Scorecard remains an essential tool for navigating these differences, helping procurement teams make smart, risk-conscious decisions.”

Some other takeaways from this year’s Scorecard are that PID and PAN results have improved. However, the module breakage rate for the mechanical stress sequence (MSS) and the hail stress sequence (HSS) has increased. HSS results have shown that 3.2mm glass-backsheet modules and hail-hardened designs are significantly less susceptible to glass breakage than 2.0mm glass-glass modules.

“The number of hail-hardened modules that we’ve tested is not as high. But so far, the indications show that hail-hardened modules have a lower breakage rate for both 2.0mm glass-glass and 3.2mm glass-backsheet. That shows a trend in the right direction,” said Erion-Lorico to PV Tech.

PV Tech Premium spoke with Tristan Erion-Lorico about the latest results of this year’s Module Reliability Scorecard and how cost cuts could have been one of the issues for the increase in test failures.

Tristan Erion-Lorico will be a speaker at this year’s fourth edition of PV ModuleTech US in Napa, California, on 17-18 June 2025. The conference will address the module landscape and map out the PV module supply channels to the US in the coming years. More information, including how to attend, can be read here.

The article has been amended to include a quote from Erion-Lorico on hail testing results.