The European Union’s REPowerEU strategy could be thwarted by higher material and module costs as a “perfect storm” looms over the sector following the pandemic, according to analysts Wood Mackenzie.

On 18 May, and in response to Russia’s invasion of Ukraine, the EU unveiled its updated EU Solar Energy Strategy as part of its overall REPowerEU programme, which is targeting 320GWac/400GWdc of solar PV by 2025 and almost 600GWac/740GWdc by 2030.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

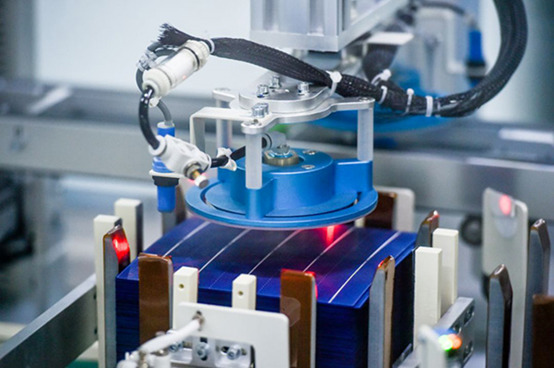

The European Commission (EC) has described solar PV as the “kingpin of this effort” but WoodMac warned the technology’s contribution was in jeopardy from high raw material costs, logistical challenges and rising module prices.

Last year saw a “perfect storm of covid disruptions” that caused a “rapid recovery in demand from solar installations, fast-increasing freight rates and high solar raw materials prices”, which have pushed up the cost of module by more than 20%, said WoodMac senior analyst Theo Theodorou.

Moreover, prices for key solar raw materials such as polysilicon, silver, aluminium, copper and steel have all reached multiyear highs, said Theodorou.

PV Tech’s PV Price Watch has been tracking the price of modules and raw materials since volatility began after the pandemic, with the latest update noting how modules prices are continuing to rise as elevated polysilicon and wafer costs take their toll.

The price of polysilicon has tripled in the last 18 months because of COVID-19 restrictions and China’s power crunch delaying new capacity additions, according to WoodMac. And while new polysilicon capacity is expected to rebalance the market and reduce costs, this will not happen until next year at the earliest, it added.

The REPowerEU initiative, which was broadly welcomed by the industry, has the potential to add 420GW of new solar capacity by 2030 but “Europe needs to navigate this high price environment and act fast to develop a local solar supply chain to achieve its targets,” said Theodorou, adding that more sanctions against Russia and volatile energy markets would compound the situation further.

One key means of achieving the targets set out under REPowerEU was to develop a European manufacturing based and built out the continent’s supply chain, Theodorou suggested.

WoodMac noted how Europe’s main producer of polysilicon, Wacker Chemie, which produces roughly 60 kilo-tonnes a year, exports most of this to China in the absence of downstream capacity in Europe to convert this into modules.

For Europe to consume its current polysilicon production it would need to increase its ingot and wafer manufacturing by a factor of 10 and further downstream manufacturing of cells and modules by 21-fold and 3-fold, respectively, WoodMac said.

Indeed, leading solar manufacturers – from Qcells to Canadian Solar and JinkoSolar – have urged European governments to implement tax credits and other financial incentives to stimulate domestic PV manufacturing, which was demanded by industry bodies even before the announcement of the REPowerEU strategy.

“To achieve REPowerEU goals and create a local solar supply chain, current capacities need even more aggressive expansions at three times more polysilicon, 20 times more wafers, 42 times more cells, and 6 times more modules,” said WoodMac.

But there are some factors that cannot be solved in the short term. The price for antireflective ultra-clear glass – the main material used for the front side cover of solar modules – is under pressure due to increasing costs of natural gas and tin, while materials such as aluminium, galvanised steel and copper all saw price increases of more than 30% since last year, WoodMac said.

And, “there is not a lot that can be done to reduce the intensity of use in the short term,” it added.

PV Tech will be exploring what REPowerEU means for Europe’s PV industry in our next PV Tech Insights webinar, entitled What REPowerEU means for European solar, featuring guest speaker Naomi Chevillard, who is head of regulatory affairs at SolarPower Europe. More details on the webinar, including registration, can be found here.