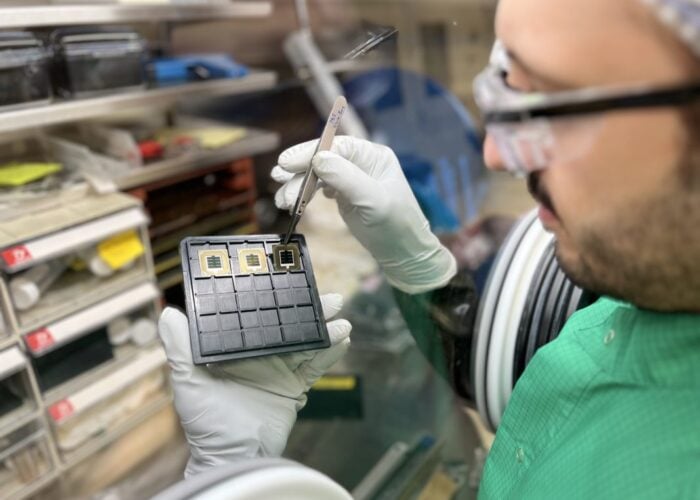

Japanese conglomerate Toshiba said it has developed a new coating method that boosts the power conversation efficiency of large, polymer film-based perovskite modules to a new high.

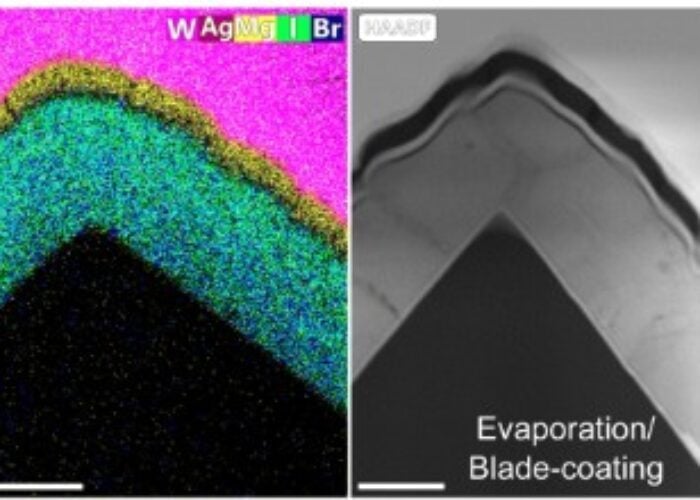

The record 15.1% efficiency was achieved for a 703cm2 module thanks to a one-step meniscus coating method that uses improved ink, film drying processes and production equipment to form a uniform perovskite layer.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

This process halves the steps for deposition of the perovskite layer and raises the coating speed to a rate that meets mass production requirements, according to Toshiba.

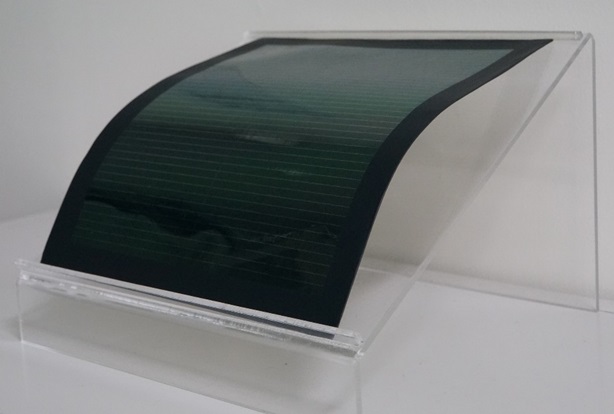

The company said the lightweight and flexible design of polymer film-based perovskite modules means they can be installed in locations where it is difficult to use crystalline silicon modules, such as low load-bearing roofs and office windows.

Toshiba plans to continue its research on perovskite modules, with an aim of increasing the production conversion efficiency to 20% or more and enlarging the active area to 900cm2, the size it said is required for practical application.

The company’s perovskite progress comes after Japan’s prime minister, Yoshihide Suga, said last year that the country would promote the research and development (R&D) of next-generation solar technologies as part of efforts to reach net zero by 2050.

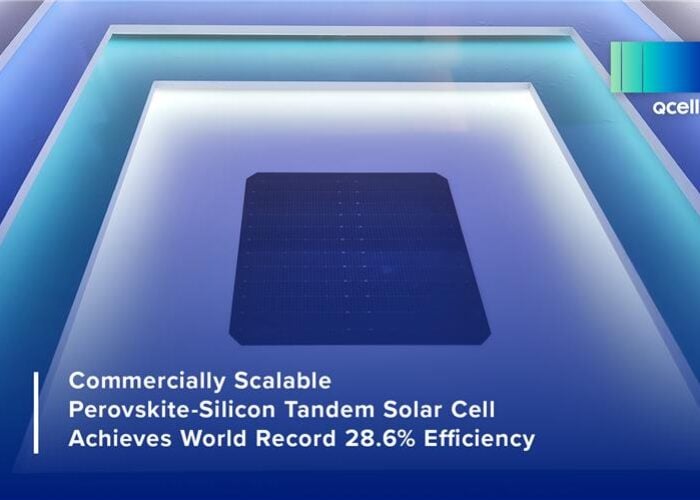

Elsewhere, the US Department of Energy recently earmarked US$40 million for 22 R&D projects focused on perovskite materials and a further US$3 million to support start-ups scale the commercial production of perovskite technologies.

There has also been a host of recently published research into perovskites, including a project in Australia that increased the power conversion efficiency of perovskite cells through the use of hair clippings. Researchers in the UK, meanwhile, found that perovskite materials’ lifespan can be extended from much less than a month to more than four months if they are stored at low temperatures.