Ryan D. Quint, senior manager at North American Electric Reliability Corporation take a look at the key considerations – and difficult balance – of managing grid connection from a transmission operators point of view.

The electric power system is an ecosystem of millions of interconnected components – breakers, relays, transformers, inverters and so on – but it is also an ecosystem of entities that work together to ensure reliable and secure delivery of electricity to end-use consumers. As clean energy policies around the world are rapidly accelerating the interconnection of wind, solar photovoltaic (PV), battery energy storage systems (BESS) and hybrid plants, it is important for us to remember that each entity has a role to play in ensuring the effective transition towards very high penetrations of inverter-based resources. The energy transition is a shared experience – we must work together to keep the lights on while undergoing rapid technological change.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Or continue reading this article for free

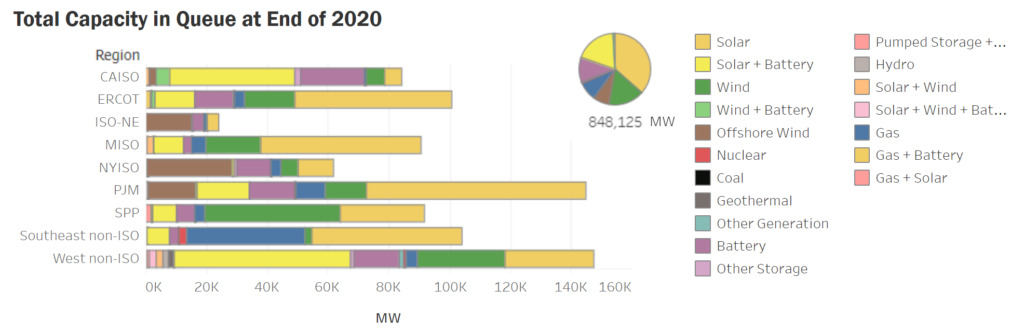

We hear time and again that the renewables development community faces a rigid, inflexible interconnection process. With over 800GW of resources “stuck” in the interconnection queues in the US, the development community is frustrated at the challenges they face when seeking to interconnect new resources to the bulk power system.[1] We most commonly hear that the greatest barrier to interconnecting more clean energy resources (and updating existing ones) is the “broken” generator interconnection process, and difficulty meeting interconnection requirements and study processes that are prerequisite for commercial operation.

Some of the challenges we most commonly hear from the development community include:

- Inconsistent interconnection processes across regions

- Unpredictable, ever-changing and complex modeling, performance and commissioning requirements

- Opaque or unfair interpretation of rules

On the flipside, we hear a number of related complaints from transmission planners and operators, such as:

- Rapidly evolving technologies (e.g. grid forming inverters, batteries, hybrid plants) require new modelling, studies and processes

- Little trust in submitted study models, incorrect or poorly parameterised models, and lack of supporting materials to validate the models

- Gaming the interconnection queue with multiple requests for the same project, leading to unnecessary re-studies and a high dropout rate

- Unreliable real-time performance of existing resources yet no clear corrections to models or equipment to address known reliability issues (e.g. findings from NERC reports)

Both sides present valid frustrations and underline a clear need for improvements to the interconnection process. We should not consider this issue an “us versus them” situation; both sides generally want safe, secure, reliable, streamlined and economical interconnection of new clean resources – and to avoid the next major blackout. The repercussions and backlash from that bad day are just too great a burden to bear.

The need for reform

The need for an improved generator interconnection process has been identified in multiple NERC reports, most recently the Odessa Disturbance Report analysing the widespread loss of solar PV resources in the Texas Interconnection.[2] In addition, NERC has also strongly recommended all transmission service providers modernise and improve their interconnection processes and requirements to support increasing levels of inverter-based resources.[3] A long-term solution – in the form of a modernised and improved regulatory process that unifies and simplifies the connection process without compromising the sufficiency of analyses – will inevitably take time; however, we cannot wait to make changes to requirements and existing processes to manage the interconnection queues of today.

We are beginning to see movement across multiple regions regarding interconnection process reforms. The Connections Reform Initiative is addressing concerns with delays and complexity connecting to the Australian National Electricity Market.[4] The Federal Energy Regulatory Commission (FERC) recently released an Advanced Notice of Proposed Rulemaking (ANOPR) seeking to reform, streamline and modernise the generator interconnection process.[5] The Global Power System Transformation (GPST) Consortium is also seeking to develop technology to improve system reliability and streamline the interconnection process under an accelerated energy transition.[6]

Finding balance

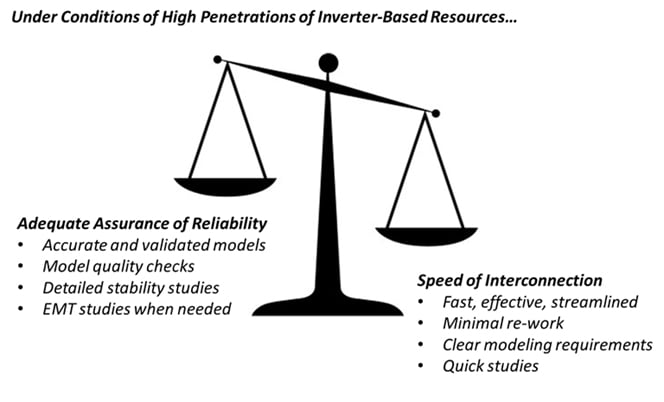

Under high penetrations of inverter-based resources, ensuring reliable operation of the bulk power system and rapidly interconnecting new generating resources are somewhat conflicting concepts that must be delicately balanced. The balancing act between these two perspectives is absolutely critical.

In a perfect world, transmission service providers would have clearly outlined interconnection process and requirements, and be able to conduct very fast and accurate reliability studies. In reality, the models submitted to the transmission planner do not represent the planned or installed equipment, or are just entirely unusable for performing studies. Model quality checks have not been properly conducted by the interconnecting customer or by the transmission planner. Or the planner has identified the need for detailed electromagnetic transient (EMT) studies due to the complexities of a high penetration inverter-based world. These add significantly more complexity, time and study work to the process. Can we simply ignore these issues? Can we avoid running studies? Can we live with modelling errors? Absolutely not! Not if we intend to keep the lights on…

Actionable recommendations

We need to stop admiring the problem and instead get actively involved in developing solutions to address these challenges. Emerging technologies being deployed on the grid present exciting opportunities but require effective policies, suitable requirements, accurate models and adequate studies. In an effort to provide useful guidance that we can act on now, I offer the following recommendations to the development community to help support our rapid energy transition:

- Understand the complexities of the interconnection process: Today’s interconnection queues are dramatically more complex than in the past when only a handful of large synchronous generators were seeking interconnection with 5–10+ year construction timelines. Today we see vastly different resources being interconnected on significantly expedited timelines. Existing processes are stressed by adequately studying these complex resources, let alone on such a quick timeline. However, transmission service providers must uphold their responsibility to identify reliability issues and develop mitigating measures. Inverter-based technologies present new and complex issues that need to be addressed. Examples include controls interactions, low short-circuit strength issues, oscillations, power quality issues, ride-through performance issues and possibly the need for grid forming inverters. These challenges are intensified and widespread as we connect more power electronic-interfaced generation to the grid. Ultimately, there is no way around it in today’s modern world; however, these reliability issues can be addressed with detailed modeling and studies that must be performed during the interconnection process.

- Prepare to meet interconnection requirements: Interconnecting customers should prepare for the requirements established to ensure reliable operation of the bulk power system. In addition to NERC and FERC requirements, transmission service providers have their own unique requirements. NERC released a reliability guideline[7] strongly recommending these entities comprehensively update their interconnection requirements to be clear, consistent and appropriate for inverter-based technologies. Transmission planners will have detailed modelling, validation and study requirements throughout the process. The market operator, where applicable, will also have interconnection requirements, business practices manuals, operating guides, etc. All these requirements serve a vital role and must be adhered to at all times. As the technology landscape rapidly evolves, developers should expect that requirements will evolve at a similar pace to keep up with changing grid reliability needs. Coordinate with your transmission service provider and other applicable entities to address issues early.

- Ensure model quality and accuracy during interconnection studies: This point cannot be stressed enough. Model accuracy and model quality matters, and is one of the biggest challenges with the interconnection process today. NERC in its analysis of widespread solar PV loss events has highlighted that the unreliable performance of solar PV resources across multiple large disturbances stem from inaccurate modeling and studies during the interconnection process. In many cases, models provided to the planner were inaccurate , were not validated, or were not checked adequately by the transmission planner; therefore, the resource operated in an unstudied state. This problem needs to be fixed as quickly as possible. Providing a model is necessary but not sufficient – that model must match installed equipment. NERC has strongly emphasised the need for transmission planners to develop comprehensive model quality checks pre- and post-commissioning to ensure the model matches actual equipment and settings. If a discrepancy is identified, mitigating measures should be implemented immediately. Prior to commercial operation, this may include re-study or additional documentation from the developer. After commissioning, this may require curtailment or other consequences until a solution is implemented. Developers should expect that transmission planners across North America, and likely around the world, will put significantly more emphasis on ensuring model quality prior to conducting studies. This will require more assurance in the form of oneline diagrams, attestations from OEMs, specification sheets and factory test reports. Identifying these issues late in the interconnection process will delay it. Refrain from using models of generic equipment to “get through the queue”; this will only be flagged later and void all studies.

- Understand material modification and pick equipment early: Equipment needs to be locked in as early as possible. The later specific equipment is selected, the longer the interconnection process will require. Planners must study the actual equipment being installed. Using a model of generic equipment greatly increases the chances of requiring a re-study once parameters are finalised. This is a significant pain point for developers but planners absolutely need to study the performance of the expected actual equipment being installed. Interconnection requests with speculative data should expect that the interconnection process could be delayed until appropriate decisions can be made regarding equipment, control modes, settings and other aspects of the facility. In an iterative selection process, expect re-study work and expect delays. The term “material modification” has added confusion in this area because it means too many things. There are activities underway to address these issues in North America; however, the main message is that developers should coordinate with the transmission service provider and transmission planner ahead of any modifications that will affect the electrical output or response of the facility during normal or abnormal conditions. Selecting equipment and settings early and minimising equipment modifications will significantly help expedite the interconnection process.

- Establish strong relationships and contractual language with OEMs: Developers and plant owner/operators should develop strong working relationships with the OEMs but should also ensure that their contractual language is updated to reflect requirements imposed by the transmission entities. Requirements imposed on the developer, particularly modeling requirements, are often pushed to the OEM. Consider OEMs that offer transparency, willingness and ability to provide clear documentation and post-commissioning support. For example, the industry is moving toward use of “real-code” models generated from source code from the actual installed equipment. Planners may require EMT models that include this type of code and the OEMs will need to provide this information during the interconnection process and during the lifetime of the project. OEMs should be diligent and support addressing reliability initiatives identified by utilities. Simply relying on a third-party consultant to make selections and develop models may be insufficient for meeting interconnection requirements in the future.

- Eliminate queue gaming: Many transmission service providers highlight that the same project is submitted as multiple interconnection requests. The identical projects are then withdrawn at different phases of the process as the transmission entities conduct feasibility and system impact studies. As the projects drop out of the queue (commonly due to limited transmission capacity and the need for expensive transmission infrastructure costs), this requires a significant amount of extra work involving writing updated contingency files, revising oneline diagrams, updating models and base cases, re-running reliability studies and then re-determining appropriate mitigations for reliability issues. This all adds unnecessary delay in the interconnection process. One possible solution to this issue is to raise the bar (that is presently very low) for customers to enter the interconnection queue. If only projects serious about connecting (land permitted, equipment selected, design complete, construction ready, etc.) entered the queue with a higher “down payment”, then we would see less redundancy and less delay. Last minute decisions regarding proceeding or withdrawing at every stage of the queue only lengthens the process for everyone.

- Hire reputable, highly-referenced consultants and engineering, procurement, and construction (EPC) contractors: While the developer has the responsibility of meeting the requirements of the interconnection process, the support team of consultants and EPC contractors used throughout the process are often the entities performing the work to demonstrate compliance with those requirements. The area of primary concern presently is the consulting work conducted to develop and validate the models used for studies. Again, a significant amount of re-work is needed due to errors in the models developed by the consultants hired by the development community. For example, a consultant scopes model development with a set number of hours (cost) and timeline for delivery (date). However, the consultant then finds out that the plant has mixed inverter types with one OEM providing site master control. Digging into the user-defined models and developing appropriate plant models will require significantly more time and money than expected. Therefore, the developer and consultant decide to use generic models that do not reflect the actual equipment. As stated above, NERC is calling on transmission entities to better screen for these types of errors and demand validation materials to prove the model matches reality. Developers should expect these issues to be flagged. The solution is to allocate sufficient resources and hire reputable consultants that can deliver on the results needed to meet the requirements of the interconnection queue.

- Have technical staff on-site: Investment firms should ensure that developers have technical staff on-site and available throughout the lifecycle of the project. The staff should understand the engineering, design, modeling, study work and other aspects of the facility needed to effectively meet each milestone of the interconnection process. Excluding external factors like necessary transmission upgrades, the ability to address identified issues throughout the process directly correlates with the speed in which the resource can connect. Confusion or misinterpretation of results, requirements or questions can lead to significant delays in project completion or the inability to meet technical requirements. Transmission entities will also need to ensure they are staffed with engineering staff able to model, study and analyse the response of these new resource types.

- Future IEEE 2800 Standard coming: A large body of industry experts is currently wrapping up IEEE Draft Standard for Interconnection and Interoperability of Inverter-Based Resources interconnecting with Associated Transmission Electric Power Systems,[8] which is specifying uniform minimum technical requirements for the capability and performance of BPS-connected inverter-based resources. The standard will cover an array of topics from modeling and studies to power quality and ride-through performance. The project was initiated to address challenges with the interconnection process and gaps in reliable operation of inverter-based resources on the BPS, of which one of the key drivers were the ongoing widespread loss of solar PV disturbances in North America. The standard was recently approved by the IEEE Standards Association RevCom[9] and received very high balloting approval from industry. Note that IEEE standards are voluntary until an authority governing interconnection requirements enforces them. In the case of P2800, industry is expected to fully and comprehensively adopt the future IEEE 2800 standard and its complementary 2800.2 testing and verification standard.[10] The OEMs and development community should be aware of this future standard’s use, and prepare to meet all requirements and recommendations outlined in the standard as they will very likely be put into effect soon.

It is incumbent for us to recognise the gravity of the work we are doing. In the U.S. alone, nearly 400 million people depend on reliable and secure delivery of electric energy to fuel every facet of modern society. We cannot let the balancing act of ensuring reliability and interconnecting new resources quickly lean too far in either direction. Focusing too much on reliability aspects will hinder interconnection of low-cost and clean energy resources; however, leaning too far towards quickly interconnecting resources without enough due diligence will be extremely costly for all parties involved particularly when the next widespread outage affecting millions is linked to the unreliable operation of the renewable resource fleet. We can do our best to ensure this does not happen – but recognise that providing that assurance takes time during the generator interconnection process.

Author

Ryan D. Quint, North American Electric Reliability Corporation

Ryan Quint is the senior manager of BPS Security and Grid Transformation at the North American Electric Reliability Corporation. His primary focus areas include grid transformation, enabling emerging technologies, security integration, and integration of inverter-based technologies and distributed energy resources. Prior to joining NERC in 2015, Dr. Quint worked at Dominion Virginia Power and the Bonneville Power Administration. Dr. Quint received his PhD from Virginia Tech and is a registered professional engineer.

References

[1] https://emp.lbl.gov/generation-storage-and-hybrid-capacity

[2] https://www.nerc.com/pa/rrm/ea/Documents/Odessa_Disturbance_Report.pdf

[3] https://www.nerc.com/comm/RSTC_Reliability_Guidelines/Reliability_Guideline_IBR_Interconnection_Requirements_Improvements.pdf

[4] https://aemo.com.au/consultations/industry-forums-and-working-groups/list-of-industry-forums-and-working-groups/connections-reform-initiative

[5] https://www.ferc.gov/news-events/news/advance-notice-proposed-rulemaking-building-future-through-electric-regional

[7] https://www.nerc.com/comm/RSTC_Reliability_Guidelines/Reliability_Guideline_IBR_Interconnection_Requirements_Improvements.pdf

[8] https://standards.ieee.org/project/2800.html

[9] https://standards.ieee.org/content/ieee-standards/en/about/sasb/revcom/index.html