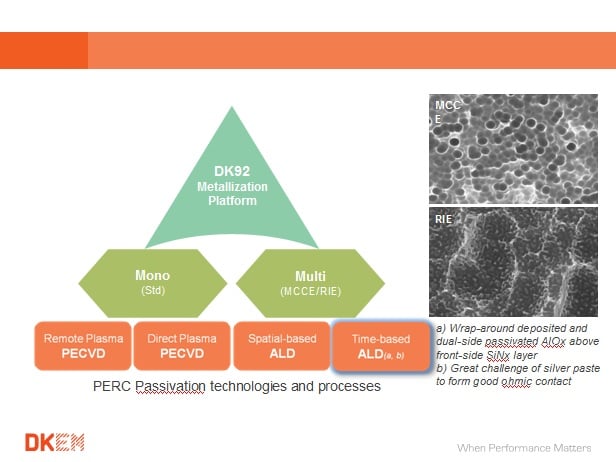

DK Electronic Materials Inc. (DKEM) has launched a new generation of front-side metallization paste. ‘DK92’ series front-side metallization pastes have been developed to be compatible with different passivation technologies and processes for PERC solar cells, including ALD (spatial ALD, and time-based dual-side passivated ALD), PECVD (remote plasma and direct plasma) as well as other non-AlOx passivation solutions to boost the diversified PERC technologies and to further lower the LCOE.

Problem

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

The consistency of performance and productivity of PERC technology is not expected to be achieved with different passivation technologies such as ALD (spatial ALD, and time-based dual-side passivated ALD), PECVD (remote plasma and direct plasma) as well as other non-AlOx passivation solutions because of the intrinsic limitation of conventional front-side silver paste. One of the challenges for time-based dual-side passivated ALD technology is the need to etch the SiNx/AlOx stacked layer to form a good Ohmic contact with the emitter due to the mismatch between front-side silver paste and dual-side passivated AlOx and the significant increase of series resistance and ratio of EL of cells and modules.

Solution

Through continuous collaboration with industry leading PERC multi/mono cell makers, DKEM has launched a new generation metallization paste, which could reduce firing temperature by 10-15 degree C, compared to DKEM's previous DK91B paste, which is approximately 20-30 degree C lower than industry benchmark conditions for PERC cells. The DK92 series is claimed to demonstrate a superior process window and compatibility with different contact requirements and diversified passivation technologies and processes. Specifically for dual-side passivated ALD, a breakthrough of front-side silver paste has been achieved with improved Ohmic contact and about 2mV U c gain from low temperature firing. Furthermore, DK92 series could solve the wrap-around deposition issue of AlOx on the front-side of PERC cells and rear-side of N-PERT cells if the passivation process is not fully optimized.

Applications

Metallization of PERC cells including ALD (spatial ALD, and time-based dual-side passivated ALD), PECVD (remote plasma and direct plasma) as well as other non-AlOx passivation solutions.

Platform

DK92A front-side silver paste for ‘Black Silicon’ multicrystalline PERC cells provides more than 1 N/mm adhesion enhancement on Black Silicon textured wafers with superior low-temperature firing property (-20-30oC over industry PERC benchmark) and a contact window enlarged to >120 Ohm/sq. The paste can achieve >20.20% efficiency for Black Silicon PERC multicrystalline cells. A special version has been developed for wrap-around deposited and dual-sided passivated AlOx for front-side PERC cells. Single print, dual print and knuckle-free screen versions of the paste are also available. DK92A is compatible with additive and Black Silicon textured diamond wire wafers with >19.20% efficiency over standard BSF cells. DK92B front-side silver paste for PERC mono cells provides an innovative glass frits that is claimed to significantly decreased the EL ratio from non-uniformity of firing temperature and diffusion control, resulting in >0.1% efficiency gain with dramatically improved production yield. Novel contact design recovered R-sheet level of PERC monocrystalline cells that is claimed to enable higher R-sheet, boosting cell conversion efficiencies to >21.6%. A special version for wrap-around deposited and dual-side passivated AlOx for PERC front-side and N-PERT rear-side cells has been developed as well as single print, dual print and knuckle-free screen versions being available.

Availability

Currently available.