Renewables developer EDF North America has signed an agreement with solar recycling firm Solarcycle to recycle all damaged or broken solar modules from its utility-scale, distribution-scale and on-site solar installations.

A press release from EDF Renewables said that the agreement would cover modules “damaged or broken during construction and operation”. Whether there are plans long-term end-of-life framework, rath than using cheaper landfill, was not made clear.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

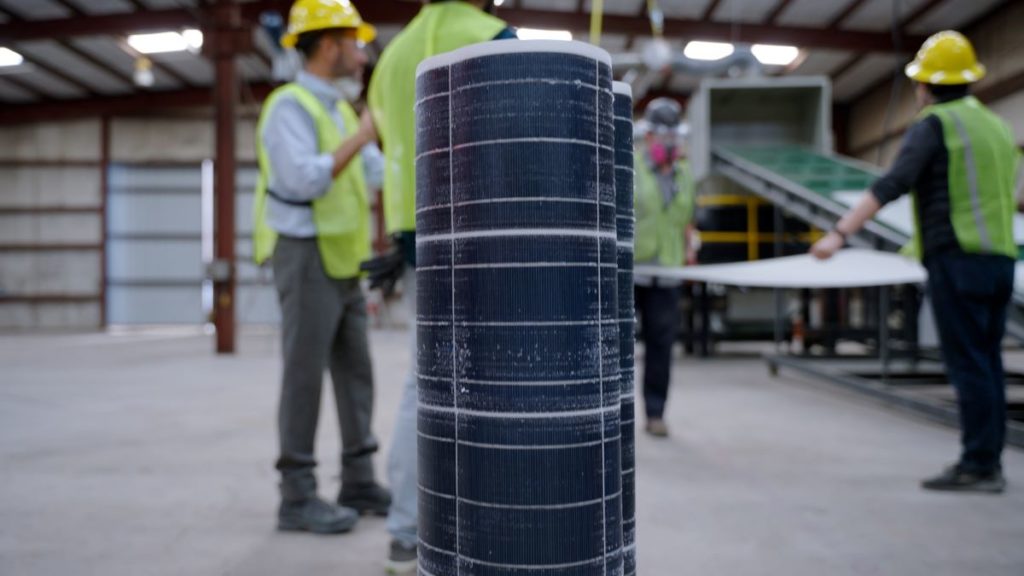

EDF said that it chose Solarcycle for the partnership due to its “proven high-value recycling process”. Solarcycle’s recycling model is based on extracting maximum value from PV modules – notably the silver and copper alongside the glass and aluminium framing of the modules – to make the process as financially viable as possible to asset owners.

Solarcycle said that its processes allow for the extraction of 95% of the value from a recycled panel, compared with an industry norm of under 50%. The raw materials extracted from modules from EDF Renewables’ projects will be sold back into the supply chains of the “next wave of solar manufacturing in North America”.

Edgar Puerto, associate director, strategic procurement at EDF Renewables said: “As a company, we have committed to developing the recycling capability of our clean energy assets, starting with solar. We view this as a key strategy for reducing our greenhouse gas emissions and catalysing a new domestic supply chain for made-in-America solar products.”

PV Tech Premium spoke with solar manufacturer Maxeon in July about this “new domestic supply chain” and the potential for recycling and rigorous component sourcing to give birth to a circular solar economy.

Jesse Simons, chief commercial officer and co-founder of Solarcycle said: “We are proud to partner with EDF Renewables, who went deep with us, with multiple visits to our factory, extensive audits and a competitive RFP process. Today’s announcement should be a sign to other global companies that recycling technology is ready today, and Solarcycle is a preferred choice for companies with a commitment to safety, quality, environmental compliance, sustainability and price.”

The company, which is based out of its recycling facility in Texas, has other strategic agreements in place with US developers and asset owners. Notable among them are deals with Silicon Ranch, AES Corporation and Danish developer Ørsted. However, as it stands, the majority of broken or end-of-life solar panels are not recycled.

In another conversation with PV Tech Premium earlier this year, Solarcycle emphasised that their goal was to “go for the silver” when recycling panels, as it’s the highest-value component. Researchers have predicted that with current technology trends and deployment rates, the solar industry will account for the overwhelming majority of the world’s silver usage by 2050.

This week solar startup SunDrive received funding from the Australian Renewable Energy Agency (ARENA) to scale-up its production line for copper-based solar cell production technology, which it said removes the need for silver whilst improving efficiency and lowering price.