Engineered Material Systems (EMS) has launched a new 561-400 series low-cost ‘snap cure’ conductive adhesive, which is designed for stringing and shingling crystalline silicon and heterojunction solar modules.

Problem

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Snap cure conductive adhesive are mostly employed in high volume production processes, due to dispensing ease and rapid adhesion at relatively low temperatures and high strength on a variety of substrates in less than one minute they also need to provide low shrinkage after curing and low stress characteristics.

Solution

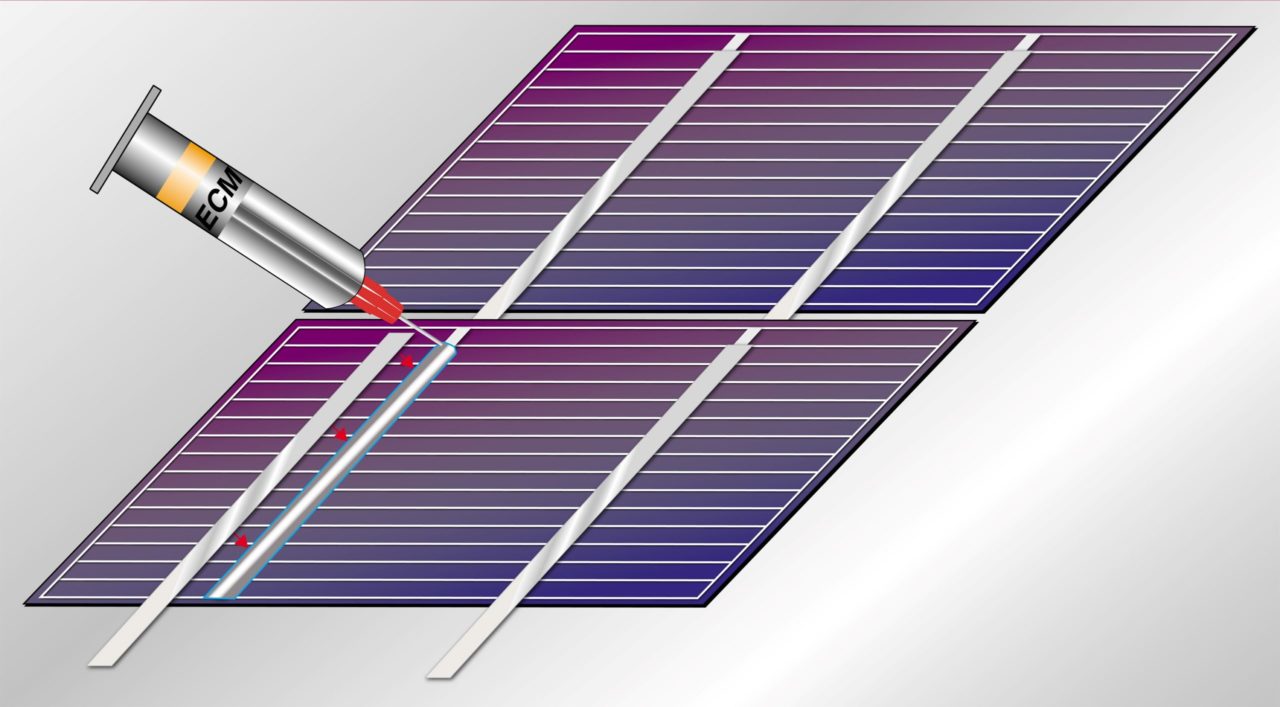

The EMS 561-400 series is used in modified ribbon stringers as the adhesive is more stress absorbing than solder to withstand the rigors of thermal cycling and processes at lower temperatures than solder. EMS 561-400 series conductive adhesives are claimed to be 60% less expensive than pure silver-filled conductive adhesives.

Applications

Snap curing conductive adhesive for crystalline silicon and heterojunction solar modules.

Platform

The EMS 561-400 series is designed to be used in modified ribbon stringers. The material will snap cure and fixture ribbons in seconds at 150°C with enough strength to withstand module manufacturing processes until the adhesive cure is completed during the encapsulant lamination process. EMS 561-400 series conductive adhesives can be dispensed by time-pressure, auger or jetting.

Availability

Currently available.