Spanish inverter manufacturer Ingeteam and PV automation solutions company Quantified Energy Labs (QE-Labs) have performed a drone electroluminescence (EL) inspection on a PV plant.

The test was carried out on a Spanish PV plant near Zaragoza, northeast of the country, on a ground-mounted 2P tracker PV system. The drone performed an inspection of 40,000 solar panels in an 8-hour night shift. This is an increase from QE-Labs previous record of 10,000 modules per night, which required energising one PV string in sequence with an external DC power supply device.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

For this inspection test in Spain, it required an operator to turn on string current injection function from Ingeteam’s inverter control system enabling remote current injections into PV strings across string combiner boxes. This removed the necessity for manual string connections and disconnections and made the process faster, without any interruption for inspection.

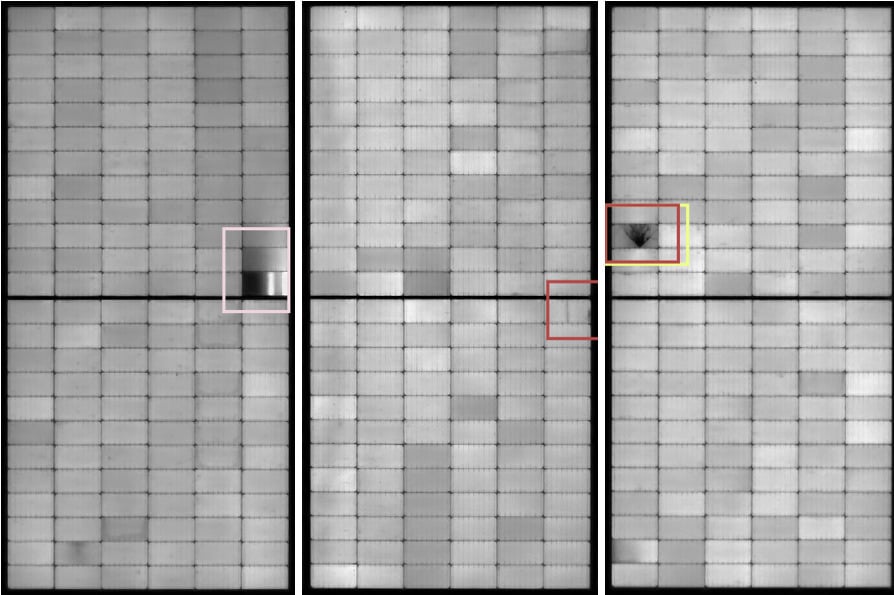

The testing was realised using Ingeteam’s INGECON SUN B Series inverter and QE-Labs autonomous drone EL mapping solution. According to QE-Labs, the inspection was conducted at a current level of 60% of luminescent solar concentrator, in order to optimise the energy use. The test required nearly 5MWh per night, in order to analyse a full 40,000 modules throughput.

Dr. Yan Wang, CEO & Co-Founder of QE-Labs, said: “This novel approach not only enhances our operational capabilities but also provides solar asset owners with a high-throughput, cost-effective solution that meets stringent quality standards.

“By making EL inspections fully contactless—similar to emerging techniques such as daylight Photoluminescence (PL) that are still in lower TRL—our market ready solution achieves significantly higher throughput in capturing EL images at the level of details be able to detect module defects such as microcrack, finger disconnection, shunted cell, cold soldering, etc. Additionally, performing inspections at night enables us to avoid disruptions to daytime energy generation.”