Switzerland-headquartered PV module manufacturer Meyer Burger has formally unveiled its range of heterojunction (HJ) solar modules for mass production.

Meyer Burger, which had previously produced heterojunction manufacturing equipment for other solar module brands, unveiled its new product line through a presentation on its website, Youtube and Facebook today (27 April), with three variants in the range.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

In addition, new production facilities will be opened in Bitterfeld-Wolfen and Freiberg, Germany, in late May to begin mass production. The equipment provider-turned-module manufacturer said in January that it wants to scale up its production capacity to 1.4GW by 2023, having been awarded €22.5 million in regional German government grants to support the establishment of a heterojunction (HJ) PV cell production plant in the country. It later announced in March it had accelerated plans to target the US market with its HJ modules.

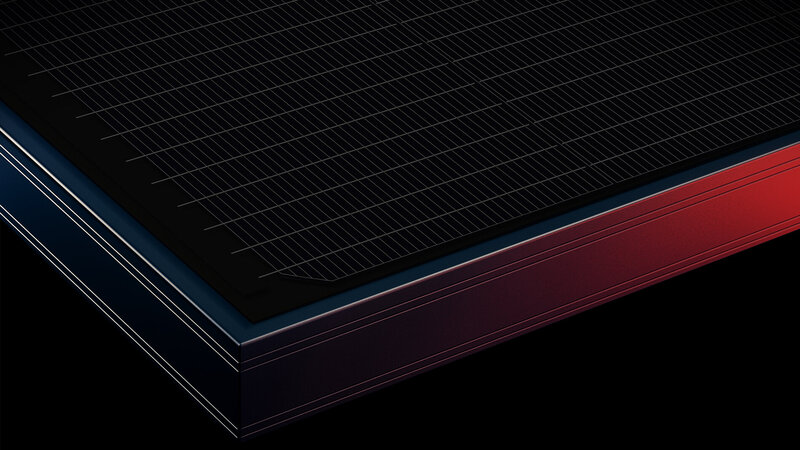

The modules, which will be available in Europe and the US, come in White, Black, and Glass variants and bring “decisive differences compared to conventional products”, according to Moritz Borgmann, Meyer Burger’s managing director.

The solar modules, which use heterojunction/SmartWire technology from the manufacturer’s factories in Germany, are designed for use in the residential and small commercial market.

The manufacturer has also claimed performance guarantees of more than 92% for its Meyer Burger White and Black backsheet modules after 25 years, and more than 93% after 30 years for the bifacial Glass modules.

“The next-generation solar cells, which we interconnect with our proprietary SmartWire interconnection technology, enable our customers to achieve up to 20 percent higher energy yield on the same roof area,” he said.

The company said in a statement that the products, which come in a conventional 60-cell through to 120-half-cut-cell formats, carry a module conversion efficiency of 21.8% and can yield up to 400Wp “without having to make the modules ever larger, as our competitors do,” Borgman said. Each module variant ways less than 20 kilograms, a critical factor for rooftop solar installations.

Product distribution is to be conducted through partnerships with the likes of BayWa r.e., IBC Solar, KdiSolar, Krannich Solar, Memodo, Solarmarkt, Solen Energy Europe and Sonepar Germany. Installers can order now, with Meyer Burger expecting to start shipments of its HJ modules from July. The company has also hired ex-SolarWorld and Q CELLS employee Sven Stoffers as its new head of sales, who is set to join the company next month.

The announcement comes after the launch of the European Solar Initiative this year, which aims to scale up the continent’s PV manufacturing industry and capture a new “boom in demand” for solar technology. A report from Capgemini Group published last year estimates that 19GW of capacity for next-generation modules could be achieved across the EU by the end of the decade, with markets such as Eastern Europe, Italy, France, Spain and Germany showing promise for potential sites.