Less rigidity during wind speeds and greater susceptibility to cracks under load pressures have been found within oversized solar modules during a new study.

The study, jointly conducted by module manufacturer LONGi and independent testing body TÜV NORD, involved carrying out both dynamic and static load tests on LONGi’s Hi-MO 5 module, which has dimensions of 2.26 x 1.13 metres, and an unnamed, oversized module with dimensions of 2.38 x 1.30m.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Or continue reading this article for free

The dynamic load test used in a wind tunnel to recreate wind speeds of up to 60m per second, while the static load test simulated bearing capabilities under a snow load equivalent to pressures of -2400 Pascal (Pa).

The dynamic load test found that the oversized module recorded a great vibration amplitude than that of the larger-size module during consistent wind speeds. It found that the large-sized module had a structural rigidity 1.3 times higher than the oversized module, creating a reduced risk of module damage during consistent wind speeds.

Further tests were also carried out to determine the performance characteristics of both modules during extreme circumstances, aiming to recreate wind speeds of up to 45m/s and 60m/s, speeds greater than those meeting the hurricane threshold (equivalent to 32 – 37m/s). The tests found that the oversized module failed during the 45m/s speed test, with the bolted screw hole becoming deformed and broken.

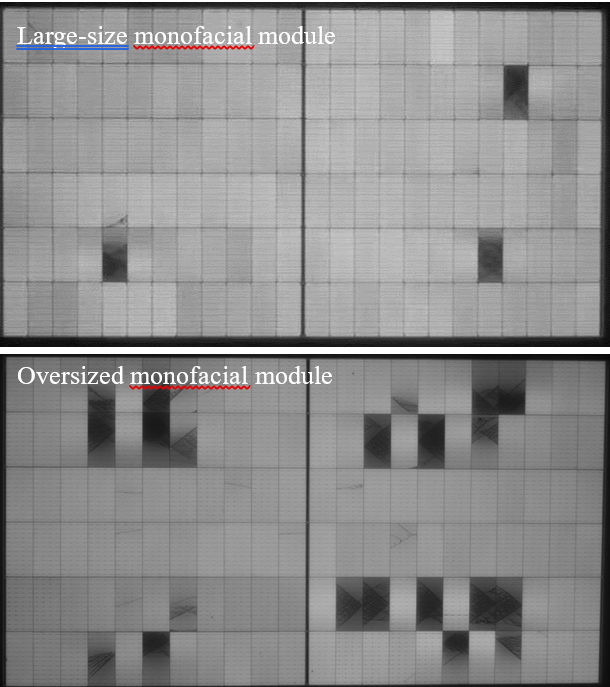

For the static load test, both monofacial and bifacial panels were assessed. The large-sized monofacial module recorded a deformation of 43.5mm during the test, less than the 67mm deformation recorded within the oversized monofacial module. The below electroluminescence image details the presence of cracks within both modules after the test.

During the bifacial static load testing, the large-sized module recorded a deformation of 38.5mm, while the oversized bifacial module recorded deformation of 63mm.

The full results of the testing can be read here.