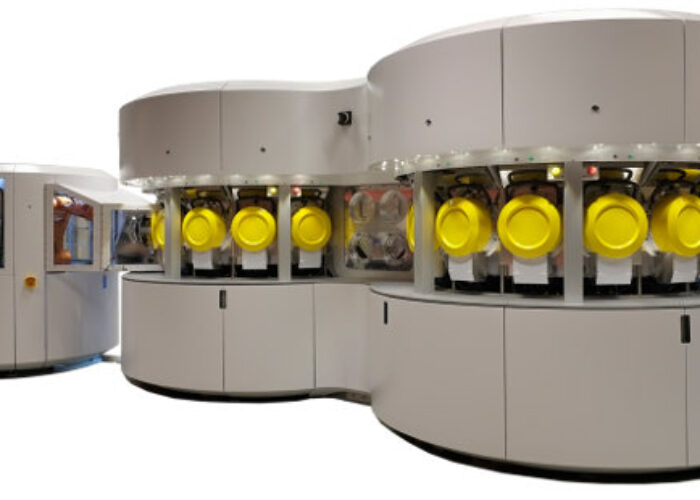

Sweden-based thin-film equipment specialist Midsummer AB said it had received an order from an undisclosed customer based in Asia for its CIGS, ‘DUO’ solar cell sputtering tool.

Midsummer said that the system would be used to fabricate lightweight flexible modules for both for portable market application and roof top installations.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

Sven Lindström, CEO, Midsummer AB commented: “This order makes Midsummer’s DUO the most widely distributed CIGS technology worldwide and confirms our leading position. Our new results showing solar modules with over 14 per cent conversion efficiency has led to increased demand for our manufacturing systems.”

Lindström was referencing a recent announcement from the company that its undisclosed customer based in Asia had passed conversion efficiencies of 14% (corresponding to 15.4% aperture area efficiency) for flexible CIGS modules, which had been tested at the testing firm, Chemitox in Yamanashi, Japan.

Midsummer claimed that the conversion efficiencies were achieved at the customer production line in normal production conditions, with standard process settings with a CIGS layer less than 1 micron in thickness. Unusually, the claims were not released by the manufacturer.

In March, 2016 Midsummer claimed Chemitox had verified CIGS solar cells (156×156 mm cell) in a flexible thin-film substrate had achieved a conversion efficiency of more than 13%.

The company said that the new tool order would be delivered in August 2017, having secured several follow-on orders from at a single customer at least in Asia, which in 2015 was cited as a ‘multinational corporation’.