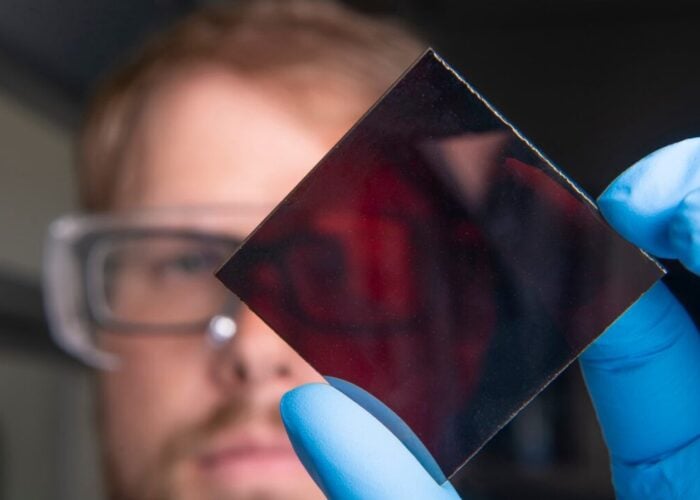

“It’s pretty clear you need to keep oxygen and moisture out”, says Saif Haque, a professor at Imperial College London and the lead author of a study into why and how perovskites, a much-talked about material that makes up one of a handful of new solar cell technologies, degrade so quickly.

Given that solar farms are exposed to the elements, this doesn’t sound like good news. But Haque says his team were pleased, even excited with the results of their tests, which focused on tin-based perovskite.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Both less toxic and less stable than lead-based versions, the structure reacts with oxygen to create tin (IV) iodide, and then iodine, which begets even more iodine in a “vicious cycle” of deterioration, meaning the perovskite cell has a much shorter shelf-life compared to traditional versions.

While it shows the problems manufacturers face right now, Haque believes the results are promising.

“This discovery helps explain why this material is unstable, it degrades in the presence of oxygen and moisture and in ambient environmental conditions,” he says. From there, we can find a way to stop it, and create a new technology that could revolutionise the solar sector.

Next-generation modules

Thin-film perovskite solar cells (PSCs) have received global attention in recent years thanks to their unique crystallographic structure that makes them highly effective at converting light photons into usable electricity. They are also comparatively cost-effective to produce.

Researchers in Japan first started using perovskite material for solar cells in 2009, although at the time their conversion efficiency stood at around just 3.8%, and would not last more than a few seconds since the electrolyte dissolved the perovskite crystals quasi instantly. Today, though, several teams have made huge strides in improving efficiency. At the end of 2020, perovskite solar cell developer Oxford Photovoltaics (PV) broke its own industry cell efficiency record after months of research on tandem silicon heterojunction/perovskite 2T (Terminal) solar cells, which has been certified by the US National Renewable Energy Laboratory (NREL) at 29.52%. The company said it is increasing conversion efficiency at a rate of around 1% per year, and partnered with module maker Meyer Burger in 2019 to buy a 200MW heterojunction line from Meyer Burger for the production of tandem solar cells at its German facility in Brandenburg an der Havel. Polish company Saule Technologies said last month it has launched the world’s first industrial production line of solar panels lined with perovskite film.

The material has attracted the attention of policymakers seeking to develop their own domestic solar manufacturing bases. Both the European Commission and the US Department of Energy (DOE) pledged to support the growth of their own manufacturing sectors, with the DOE setting aside US$40 million for 22 research and development projects into perovskite solar technologies. The DOE said last year that these cells have the “potential to make highly efficient thin-film solar cells with very low production costs.”

However, developers hoping to work with perovskites as the active layer in solar cells still face significant hurdles, hence the R&D push. Stability and durability continue to be a core issue with the material, which degrades faster than traditional silicone cells.

Research and Development

A string of new studies has been published within the last year dedicated to resolving this key hurdle. Scientists from Queensland University of Technology (QUT) used hair clippings from a barber shop in Brisbane to form an “armour” that increases the material’s power conversion efficiency in solar cells last month, while a team at the Massachusetts Institute of Technology (MIT) alongside five other universities globally applied a data fusion process to produce and test different perovskite formulations and assess their longevity. More recently, scientists at the University of Sheffield found that storing perovskite at low temperatures can extend the material’s lifespan by as much three months.

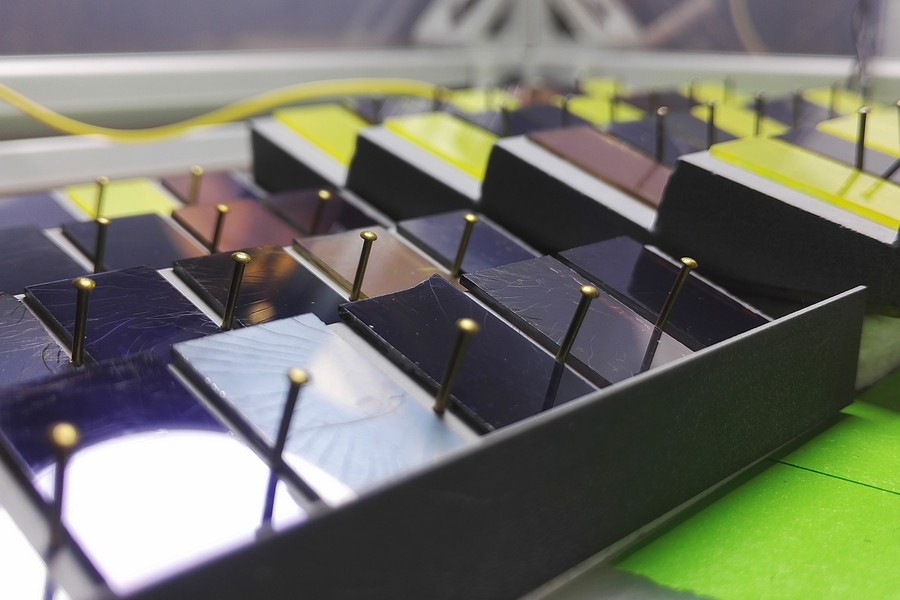

Universities have also started to establish spin-out businesses to help their findings support the development of a commercial market. Start-up Evolar, which owns prototype line equipment to scale up and test perovskite cells, was spun out of Uppsala University’s thin film solar cell research cluster and has been launched by the same research team behind Solibro, the Copper Indium Gallium de-Selenide (CIGS) solar module specialist acquired by Q CELLS in 2006. It has since received substantial funding from Norwegian investor Magnora to scale up its technological developments and has said it will seek partnerships with solar manufacturers to scale and test the technology, with a view to generating revenues through design, engineering, software and royalties.

Chief executive Mats Ljunggren tells PV Tech that Magnora’s latest investment will be used to scale up the start-up’s PV Power Booster technology to full module size, and to finalise equipment designs.

“As any other in the business, we are finetuning the composition of the perovskite cell stack” Ljunggren says, but declined to give any further detail on the company’s commercial efforts to improve stability. “As we are addressing the perovskite-silicon tandem area, it is crucial to be successful in matching the perovskite durability level with the one for the silicon layer.”

Lead halide models have been among the most successful in terms of stability, but throw up more complicated issues relating to their environmental impact. A 2020 study published in Nature Communications found that, while many attest that the lead perovskite used in solar cells carries a low risk compared to other electronics that use the metal, lead leaking into the ground can enter plants, and consequently the food cycle, “ten times more effectively than other lead contaminants already present as the result of the human activities”.

“The issue of stability remains a problem”, Haque says, but adds there are “very encouraging” studies emerging worldwide in how to extend their lifespan. Having lead in the system itself is also problematic, he adds, due to its toxicity and potential environmental harm. “Trying to replace the lead with something less toxic, more environmentally friendly is important.”

It is why alternative metals have become increasingly important in the development of perovskite solar cells. Oxford PV’s tandem perovskite cells are based on tin, and Ljunggren says Evolar’s line equipment is not limited to use for just lead-based materials.

Haque tells PV Tech that tin-based structures have proven the most promising in terms of conversion efficiency and durability, but they are less stable still than lead-based versions. Researchers from his department and from the University of Bath published findings of their own earlier this month. Also in Nature Communications, the study identifies the reasons why tin-based perovskite destabilises quickly, potentially shining a light on how to prevent degradation right from the production process.

“[Tin-based perovskites] very quickly react with oxygen to form a number of products and one of those products is tin (IV) iodide,” he says. “Tin (IV) iodide can very quickly convert into iodine in the presence of moisture and oxygen. Iodine acts as an oxidant, it reacts with the perovskite to generate more tin (IV) iodide… It facilitates that further breakdown of that perovskite into tin (IV) iodide, and then you end up with this vicious cycle.”

Haque warns that this reaction needs to be considered right from the film production process. P-type self-doping and the presence of excess holes in tin perovskite is problematic, he says, and this self-doping is detrimental to device performance. But a focus on interlayering in the device stack has produced perovskites with better durability.

“If you process the perovskite film on a what we call a hole transport layer or a hole extractor, that’s able to take some of these holes out of the tin perovskite and the net effect of that is to improve the stability.”

Another study published earlier this week by researchers at New York University found that fabricating perovskite solar cells using carbon dioxide in the doping process under ultraviolet light not only shortened the fabrication and process time, but also increased stability and conductivity.

Studies such as these have become invaluable to the companies that are seeking to capitalise on mass production of perovskite solar cells. Aside from durability issues, however, keeping production costs low remains a competitive challenge. Ljunggren says his start-up’s business model focuses on the sale of equipment for producing perovskite-silicon tandem panels, which means it is “crucial…to show low enough capex to be attractive for our customers”.

Ljunggren says that Evolar benefits from direct collaborations with R&D groups and its own connection to Uppsala University, but “we are always scanning and evaluating published R&D achievements and are open to include the best ones”.