Utility-scale solar projects are, for the most part, built in a similar pattern. They start with civil grading, adding the piles, followed by the racking, trackers and modules. Once all of this is done, you add the electrical balance of systems (eBOS).

According to Ryan Schofield, vice president of eBOS at Nextracker, one issue with this process is that eBOS manufacturers usually receive the project’s site layouts at a very late stage.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

“I’m a little biased toward eBOS, but to me, it’s probably one of the most important pieces. It’s one of the lower dollar amounts that you’re going to spend on an overall price per watt basis. But it’s the most crucial stage because it comes later in the project, and it’s what’s generating your power,” explains Schofield.

Schofield says designing an eBOS product within Nextracker, such as the recently launched NX PowerMerge, gives the company an advantage over traditional eBOS manufacturers, as it can complete that work process much earlier.

“Now that we’re able to introduce eBOS in the early stage, paired alongside the trackers, we’re able to understand what the layouts look like, how long the tracker rows are, the module types or the site conditions – everything that most eBOS manufacturers are not permitted early in the design phase,” says Schofield.

He adds that being able to get in early in a project allows the eBOS division to innovate and be creative with the design.

Moreover, receiving feedback from EPCs on some of the recurring issues happening on several projects, or ones specific to a type of terrain or tracker, allows the company to work on the design and innovate the overall architecture of the eBOS products.

Importance of expanding beyond PV trackers

This is even truer when considering that Nextracker acquired electrical infrastructure manufacturer Bentek Corporation in May of this year, which helped the company expand its portfolio with a suite of products in the eBOS field.

“With Bentek, we saw the right fit to go and pick a company that was ready for growth, undercapitalised, with a very valuable skill set in Silicon Valley,” says Yazan Aljani, senior director of sales for eBOS at Nextracker.

Aljani adds that combining the know-how of Nextracker’s trackers, such as NX Horizon with NX PowerMerge allows for better optimisation of the whole ecosystem and avoiding any last-minute changes from engineering, procurement, and construction (EPC) due to not being able to know exactly how much wire will be required on a given project.

Bentek was not the only acquisition Nextracker made this year; in July, the company also moved into the robotics and AI business with three new acquisitions. This was part of its ongoing strategy to offer additional technologies around its core tracker business, but also to improve and refine its existing products, and for which Schofield sees the use of robotics and AI as an ideal tool. He explains how the company is using AI to analyse data from previous projects, and pinpoint the successes and failures.

“Things like robotics and AI, what we’re able to do is we’re able to look at a wide data set and say, this project, this location, this collection type, what was a common issue that we may have seen, or what worked really well with that particular design, which allows us to in the next project moving forward.”

Combiner vs trunk connector

The launch of the new trunk connector is not intended to impose it over a combiner system, but rather to provide the best solution to a given project.

“We’ve really approached eBOS as a product-agnostic space to us, and we’re really trying to push for solving the project’s needs,” says Aljani.

Schofield adds that the goal is to focus on providing the best system type based on the project. “We’re not really here to push the combiner system on you or the trunk bus system.”

Especially given that the market share between combiner and trunk systems is evenly split, according to Aljani. Each one has its specificities, such as the combiner system being best suited for electricians as they require more skilled labour, while trunk systems are best suited for projects that are square-shaped sites but also large-scale ones such as 800MW types of projects.

“Traditionally, combiner boxes are just kind of the route that people went to centralised testing. All your fuses are in one location. You can go right to a box. You can check all your inputs, make sure your fuses are operating, and aggregate more strings into one central testing point.

“With a trunk bus, it’s a little bit more spread out, but it’s an easier install. So again, it kind of becomes a math equation on what you are really after to solve this. And there are a lot of external factors that are coming into it, such as terrain,” explains Schofield.

Meeting today’s high-voltage, high-density solar array needs

One of the features of NX PowerMerge is that it has been developed to meet the demands of today’s high-voltage, high-density solar arrays. The trunk connector can provide a 2,000V-ready solution for PV string-to-trunk bus connections. The jump from 1,500V to 2,000V systems as the new industry standard has been a topic of discussion in the past few months.

For Schofield, there is no doubt that this is “where the market will be going sooner than later”, and the compatibility of the new eBOS product with 2,000V is a response to that.

“When it happens, you need to be prepared for it. And that’s what we were trying to do, really develop that product, to have EPCs and developers comfortable with what we’re doing with the same architecture, but then be ready to transit.”

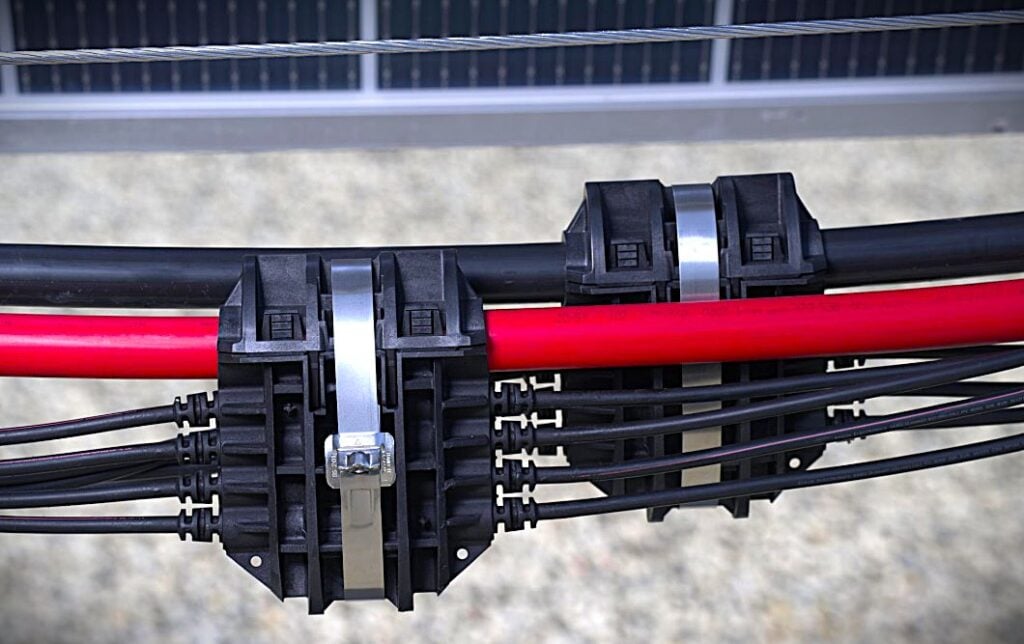

Schofield adds that another differentiator between NX PowerMerge and other trunk connectors comes down to the amperage rating, which is rated over 400 amps and supports for up to eight tap wires (6-8 AWG).

“The larger your wire, the more current that cable can carry. Which means you’re able to parallel more strings and bring more strings into each individual tap off of that. That allows you to go to higher currents and overall reduces the amount of trunk connectors that you need on a project,” explains Schofield.

Overall, even though the eBOS part comes at the end stages of a project’s construction, looping in the eBOS manufacturers into a project early on can end up saving both time and money for an EPC constructor. They’ll be better prepared for what the requirements are in terms of products needed, rather than having them either buy more wires or cut them short on-site to match the needs and size of the system.