The inclusion of a thicker aluminium oxide (AlOx) layer in tunnel oxide passivated contact (TOPCon) solar cells could provide superior resistance to ultraviolent-induced degradation (UVID).

This is according to the latest research from the University of New South Wales, in Australia, which published its findings into the testing of AlOx layers in TOPCon cells in ‘Solar Energy Materials and Solar Cells’ this week. The researchers assessed two thicknesses of AlOx layers, a thinner 4nm film that is the “cost-effective minimum” used in the solar industry, and a thicker 7nm film that is not so thick as to “affect the optical properties of the dielectric stack”.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

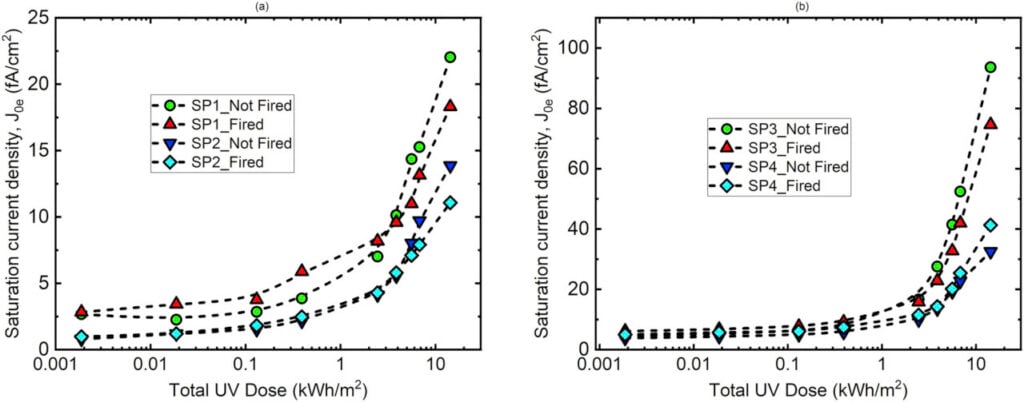

Each thickness was assessed twice, once without a diffused emitter and once with a boron-diffused emitter “to represent the structure of a finished cell’s front side”, giving four test cases: SP1 and SP2 do not include an emitter, while SP3 and SP4 do include the emitter; meanwhile, SP1 and SP3 use the thinner layer, while examples SP2 and SP4 use the thicker layer.

As shown in the graph below, SP1 and SP3 show a higher saturation current density, which the report notes is “indicating degradation of surface passivation”. As a result, the tests using a thinner layer show less saturation density, and thus less degradation, leading to the researchers’ conclusion that the thickness of the AlOx layer is a “dominant parameter in showing the degradation trend”.

The researchers note that a “complex interplay of phenomena” affects degradation, but that “the interaction of high-energy UV photons with the hydrogen-rich dielectric layers” is understood to be a key driving force.

“A thicker (7nm) AlOx layer provides superior UVID resilience by acting as a more effective barrier to the detrimental transport of mobile hydrogen,” write the researchers in the report’s conclusion. “These results provide important guidance for designing more durable passivation layers and refining accelerated testing protocols to secure the long-term reliability of TOPCon technology.”

Tackling the performance issues of TOPCon modules was a key priority for the global solar sector in 2025, as TOPCon continues to be the leading technology in the sector. Over the summer, Kiwa PVEL’s Module Reliability Scorecard showed that a record 83% of modules saw at least one failure in the testing process, with UNSW academics in particular highlighting the potential damage that UVID could do to TOPCon cells.

The AlOx assessment is the second significant piece of research into module degradation to come from UNSW this week, following a the publication of report that showed that up to one-fifth of solar PV modules degrade up to 1.5 times faster than average.