Advances in cell technology combined with increasingly complex supply chain and regulatory dynamics have created new risks for PV module reliability. Against this backdrop, Don Cowan and Mahyar Mohammadnezhad of Kiwa PI Berlin explain the growing importance of upstream diligence in ensuring long-term PV asset performance.

Understanding the long-term reliability of photovoltaic (PV) modules has long been a cornerstone of project procurement. However, evolving policy, quality and compliance developments are pointing upstream from the finished module to its most critical subcomponent: the cell.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

In recent years, manufacturing capacity has ballooned across multiple geographies, with gigawatt-scale factories producing cells using different processes, equipment and material sources. This rapid manufacturing expansion, along with the diversification of supply chains and the adoption of advanced cell architectures, has introduced heightened risks related to process variability, latent defects and compliance gaps. At the same time, global policy changes have continued to complicate sourcing strategies, as PV project developers and investors face new compliance requirements and look to manage ongoing regulatory and market influences.

Kiwa PI Berlin’s latest report, ‘The race to PV cell quality and compliance’ [1], discusses how upstream diligence at the cell level is now a key determinant of long-term asset performance and financial viability. The findings outline why structured quality assurance (QA) and quality control (QC) in PV cell procurement are essential, what our audits and reliability testing continue to reveal and how buyers can implement upstream diligence frameworks to mitigate technical and compliance-related risks for their projects. Below, we delve into why buyers should focus on PV cells and identify the key issues in cell manufacturing for 2025.

Why upstream diligence matters more than ever

For years, the PV sector’s quality assurance practices have focused on modules, the final product seen in the field. However, as recent findings from Kiwa PI Berlin show, the root causes of many module-level failures often originate in cell-level issues.

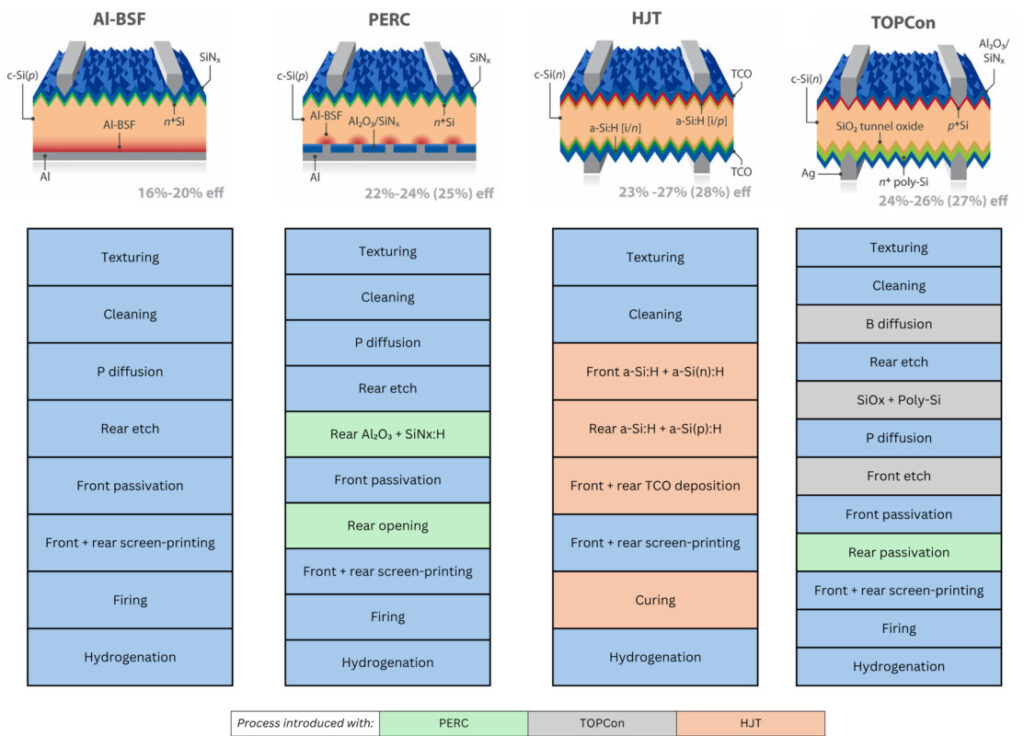

Over the last several years, the market has been shifting from deploying mostly passivated emitter and rear contact (PERC) to more tunnel oxide passivated contact (TOPCon) and heterojunction (HJT)

designs. Improvements in equipment, materials and process control have made these once-complex cell types practical to produce at high volume. TOPCon has been leading the shift, as its architectural similarity to the well-established PERC design has enabled manufacturers to repurpose existing infrastructure and leverage process expertise, thereby facilitating scale-up.

While these advanced designs offer increased cell efficiency, they also introduce new sensitivities. Cell manufacturing is rapidly expanding beyond traditional hubs into emerging regions, such as Africa, the Middle East and parts of Southeast Asia. This geographic diversification aims to mitigate tariff exposure for the US market and meet surging global demand. However, the rise of new facilities introduces significant variability in manufacturing maturity, process discipline and sub-tier supplier transparency. Even small design or sourcing changes can significantly impact cell-level traceability, reliability and the ability to maintain consistent process control.

Along with technology changes, the need for upstream quality diligence has been magnified by a wave of policy changes. For US buyers, the One Big Beautiful Bill Act (OBBBA) has fundamentally changed the compliance landscape for PV project stakeholders by tying federal tax incentives to strict prohibitions on “material assistance” from foreign entities of concern (FEOC). The compliance landscape is further complicated by overlapping regulations, including the Uyghur Forced Labor Prevention Act (UFLPA), Section 232 investigations and IEEPA-based tariffs. Managing these tariffs and other policy exposures increasingly demands transparency in a PV module’s unique bill of materials (BOM), process traceability and labour standards.

The changing landscape of cell technology and QA

The rapid evolution in cell architecture underscores a critical point: the lifecycle of PV technologies is becoming increasingly compressed. Unfortunately, this means there is an increased likelihood that reliability concerns remain undiscovered until after large-scale deployment. Accordingly, inspection and qualification procedures must evolve to address the specific characteristics of these cell technologies, incorporating advanced techniques and methodologies for accurate characterisation and analysis. Some examples of these challenges include:

- TOPCon: Requires a precisely engineered tunnel oxide layer. Even slight process variations or non uniformity can lead to tunnelling failures and passivation loss, which may result in potential-induced degradation (PID) or UV-induced degradation (UVID) field failures

- HJT: Relies on highly controlled doping and thin-film deposition steps. Poor process conditions or non-uniform layers can significantly reduce cell performance, particularly the fill factor (FF)

- Perovskite-tandem cells (emerging): Requiring advanced methods for cross-layer deposition control and long-term reliability validation

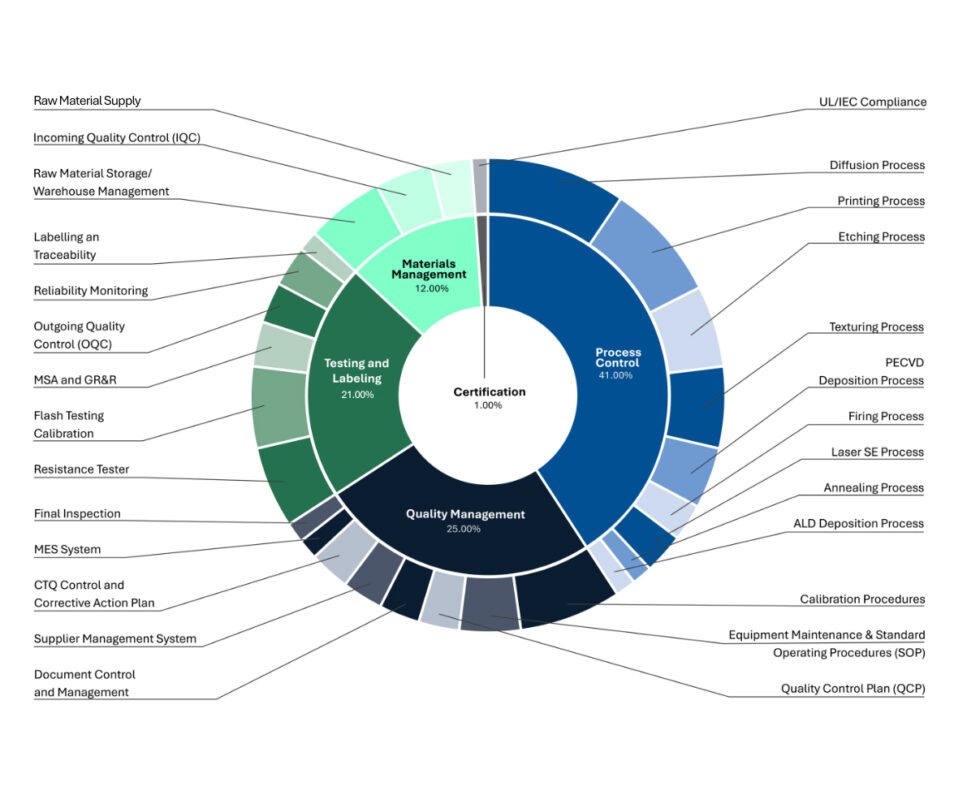

Figure 1 shows a schematic illustration of PV cell structures and corresponding manufacturing steps. Each stage of the production process is highly sensitive to variations in key parameters, such as temperature, doping concentration, gas flow rate, deposition duration, and material purity. Even minor deviations from optimised conditions can result in significant reductions in cell performance or compromise long-term reliability.

Wafer sizing impacts

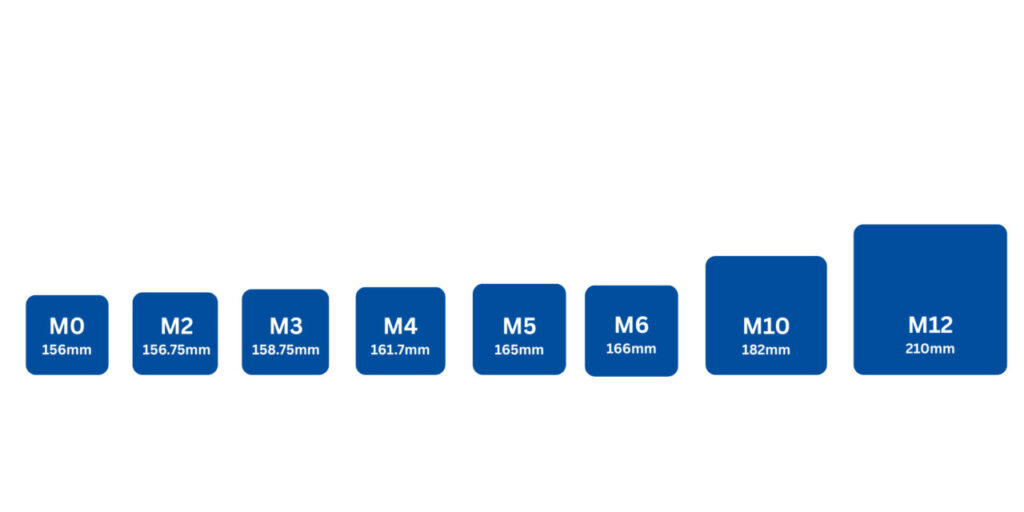

Along with new cell designs, there has also been a shift towards larger wafer formats. Driven by the industry’s goal to lower costs and increase power output per module, wafer sizes have progressed from M0 and M2 to M6, and now to M10 and G12/M12. Larger wafers help improve system-level economics by delivering higher energy yield per square meter and reducing balance-of-system (BOS) costs, which is especially impactful in utility-scale installations. As a result, M10 and G12/M12 formats have rapidly become the standard across high-efficiency cell technologies such as TOPCon and HJT.

However, larger wafers, often made thinner to reduce silicon usage, are more vulnerable to mechanical damage, including microcracks and edge chipping during handling and processing. Their increased surface area also demands tighter process uniformity, improved equipment alignment, and upgraded materials handling systems to maintain yields. Production lines originally designed for smaller wafers frequently require significant retooling to meet these requirements. Without enhanced process control and robust quality assurance, the benefits of larger wafers may be undermined by higher defect rates and long-term reliability risks, ultimately affecting performance.

Cell manufacturing process risks

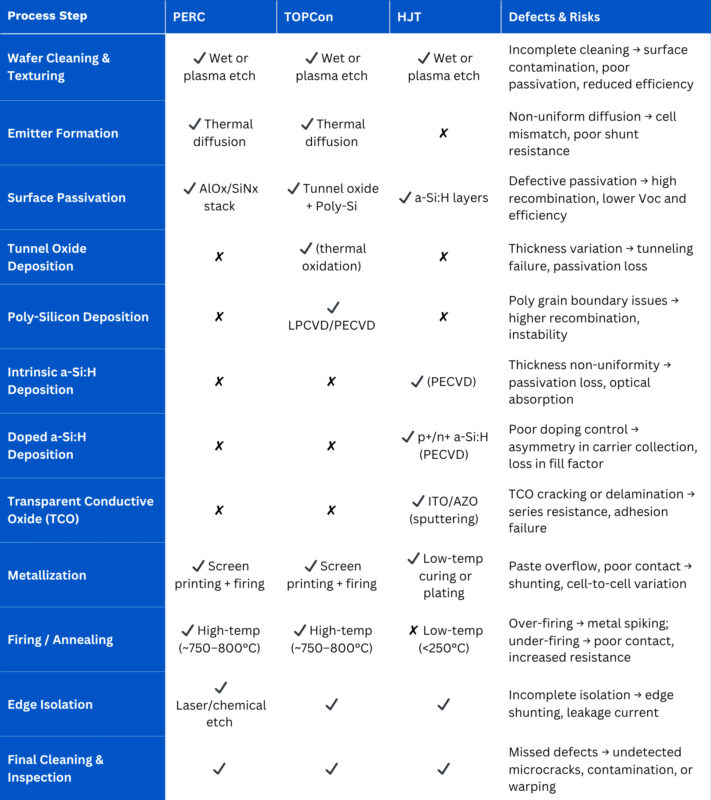

The fabrication of PERC, TOPCon and HJT cells is a complex, multistep process comprising wafer preparation, diffusion, surface passivation, metallisation, firing and final sorting. Each process step is intrinsically dependent on precise control of materials, engineered process design and systematic in-line and post-process characterisation. The structural, optical and electrical properties established throughout these stages collectively determine the long-term performance, stability and reliability of the finished cell, as well as its durability when integrated into PV modules operating under real-world stress conditions. Therefore, a fundamental understanding of PV cell quality necessitates a comprehensive understanding of its manufacturing processes.

Without rigorous quality management, quality drifts can go unnoticed until losses or reliability problems appear in the field. While these defects are not new, their frequency and impact increase as production scales and cell designs become more complex. Any deviations or errors at each step can lead to a specific defect or issues at the next step. Initial issues such as incomplete wafer cleaning could lead to surface contamination, poor passivation and reduced efficiency in all cell types. In a later metallisation step, defects such as paste overflow and poor contact can cause shunting and cell-to-cell variations. More examples of these defects and risks are listed in the table in Figure 3.

Such cell defects can contribute to field-related degradation phenomena, including potential-induced degradation (PID), light- and elevated temperature-induced degradation (LETID) and ultraviolet-induced degradation (UVID), all of which pose a significant threat to module performance and long-term reliability. Independent cell factory audits, therefore, play a critical role in providing oversight and early detection of such deviations when combined with end-product (module) reliability testing.

Factory audit defect characterisation

Maintaining long-term cell efficiency and reliability demands a comprehensive understanding of where quality risks originate in the production process. Cell QA within the factory focuses on sampling components from large-scale production batches, whereas module QA evaluates the finished modules built for a specific customer project. Differing from module product oversight and pre-shipment inspection programmes, buyers are increasingly adopting a multi-audit strategy: beginning with a cell factory qualification audit to validate process stability and quality control capability, followed by regular verification audits to ensure controls remain effective and corrective actions are closed.

Kiwa PI Berlin’s global factory audit data highlights five recurring categories of quality risks. The most common involves insufficient process control management, where even minor parameter drift can lead to long-term reliability issues. Additional findings include gaps in quality management systems, particularly in rapidly scaling production regions; inconsistent testing and labelling practices due to inadequate calibration and metrology standards; weak material qualification procedures that allow defects to enter early in the production flow; and certification compliance deviations. Collectively, these issues underscore the importance of robust upstream diligence and continuous oversight at the cell manufacturing stage. In Figure 4, we detail the quality findings observed in each category.

Process Control (as shown in Figure 4) refers to the precise regulation of every step in the PV cell manufacturing line, from wafer texturing and diffusion, to passivation, metallisation and final cell binning. Each stage requires defined parameters such as temperature, doping concentration, gas flow rate, deposition time and material purity to achieve the expected performance and reliability.

During factory audits, two main issues are frequently observed: (1) the absence of Standard Operating Procedures (SOPs) and control plans; and (2) inconsistencies between documented procedures and the actual process parameters used on the production floor. It is critical to and parameters during cell manufacturing, as even minor deviations from optimised settings can introduce hidden defects that remain undetected during routine PV module production and testing, such as electroluminescence (EL) imaging or flash testing, but may later manifest as field failures or degradation mechanisms, including PID and UVID. Therefore, process control is not just a factory efficiency measure; it is a major determinant of real-world module reliability and performance.

Materials management represents only about 12% of observed defects, but its impact is disproportionately significant. Weak incoming inspections, inadequate supplier qualification and improper storage conditions can allow substandard wafers or chemicals to enter the production line. Once a material-related defect is introduced, it propagates through every subsequent process step, eventually reaching the final module in the field. A strong materials management programme therefore acts as a critical first gate to prevent systemic performance issues. This includes traceability controls, warehouse environment monitoring and robust acceptance criteria that can identify nonconforming wafers before they are released to cell manufacturing.

One commonly observed issue is non-uniform doping during cell manufacturing, caused by using unqualified or untested materials and wafers. Doping is the process of introducing controlled impurities (e.g., boron) into high-purity silicon to form the PN junction structure required for PV conversion. Material-related issues can lead to uneven doping concentrations, causing localised resistivity variations. These defects are associated with reduced carrier lifetime, lower power output and increased susceptibility to light-induced degradation (LID) and accelerated LeTID-related performance losses over time.

If incoming material inspections fail to detect these issues, the defective cells can progress through module processing and field deployment, only becoming apparent when the system underperforms. This issue underscores the critical importance of rigorous materials qualification and inspection in safeguarding long-term PV system reliability.

What Kiwa PVEL’s testing reveals

Kiwa PI Berlin’s cell quality programme encompasses both factory inspections and end-product (module) lab-based testing through Kiwa PVEL. The lab results have likewise shown how even incremental changes at the cell level can translate into significant reliability risks.

Since the introduction of the Product Qualification Program (PQP) in 2012, Kiwa PVEL’s extended reliability and performance testing has consistently revealed how even subtle cell-level changes can significantly influence module durability and energy yield. Recent PQP test results underscore that material selection, cell architecture and process quality control remain critical to long-term reliability.

Across multiple manufacturing sites, defect rates and process variability have widened, especially among factories with new capacity installations. In some cases, differences in cell processes, coating uniformity, or metallisation created measurable disparities in efficiency and reliability. Kiwa PVEL’s extensive database of reliability test results reveals multiple examples of correlations between cell-level issues and module-level failures.

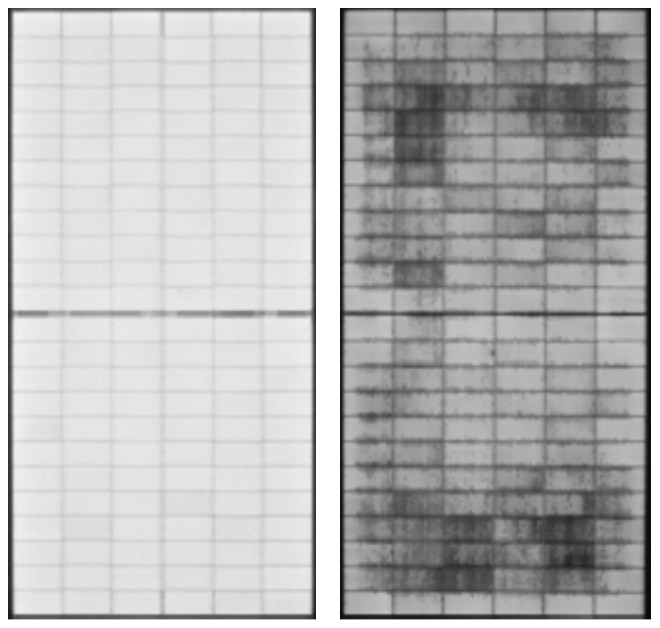

One recent example in Figure 5 showed how PID can be significantly impacted by the cell’s BOM and manufacturing process.

Here, two very similar TOPCon BOMs from the same module manufacturer, both using the same front side POE and rearside EVA encapsulant, produced sharply divergent results: 1.6% power loss for BOM 1 (making it a PV Module Reliability Scorecard Top Performer) versus 7.2% for BOM 2, which showed signs of PID-polarisation throughout its EL image.

These findings confirm that cell quality is a strong determinant of module longevity. By controlling quality upstream, buyers can directly reduce downstream warranty claims and underperformance risk.

Recommendations for buyers

Ultimately, PV cell quality assurance is about enabling buyers to improve the performance and reliability of their PV modules. At Kiwa PI Berlin, our goal is to support the industry in maintaining high generation reliability as PV continues to expand as a leading global energy source. Drawing on extensive field performance data and recent factory evaluations, Kiwa’s dynamic Procurement Quality Management Program is built around five core principles for PV module buyers:

- A PV module’s quality is determined by the quality of its component parts and manufacturing consistency

- Adequate testing prevents failures and underperformance. Warranties do not

- Manufacturers set their own quality standards unless buyers intervene

- Trust but verify the quality of delivered modules

- Have a plan to address issues before they arise

Cell manufacturing for advanced technologies demands precise handling, robust supply chain oversight and stringent traceability to ensure compliance with evolving regulatory and quality requirements. In response, PV module buyers need to implement targeted cell quality assurance measures to mitigate technical and financial risks. Adopting structured best practices helps prevent defects, underperformance, and costly warranty issues before modules even reach the field.

Therefore, Kiwa PI Berlin recommends the following for PV cell procurement:

- Qualify the product with comprehensive BOM-level traceability and pre-qualification testing through the PQP to increase visibility into suppliers, material origins, and performance

- Set contractual requirements. Integrate cell-level QA into your procurement contracts; Define measurable criteria and require supplier transparency.

- Conduct independent third-party audits to validate process control and evaluate operator competency and quality system implementation

- Verify production quality. Perform batch-level and extended reliability tests on finished PV modules to validate mechanical integrity, electrical performance, and long-term durability

- Engage an experienced technical advisor prior to and throughout the procurement process. Early involvement ensures that procurement decisions are aligned with the overall project strategy, regulatory requirements and financial objectives

PV module buyers need to take a proactive approach at every stage of the project, from procurement and production through to delivery, to ensure that equipment quality is maintained throughout the entire lifecycle. A robust and well-structured procurement process integrates multiple layers of oversight, including thorough product qualification, clearly defined contractual requirements, comprehensive factory audits, detailed production inspections and careful on-site validation. By systematically applying these best practices, buyers can establish a procurement framework grounded in transparency, data-driven decision-making and accountability.

The road ahead

The PV industry is entering its most promising yet challenging decade. As cell technology pushes efficiency boundaries and more capacity is installed, the complexity of maintaining quality at scale will only grow. Collectively, market and policy dynamics have redefined the PV cell as a strategic compliance checkpoint, where supply chain complexities, regulatory oversight and technical performance intersect.

In this environment, quality assurance at the cell level is not an optional safeguard, but a critical part of procurement. Stakeholders who proactively invest in detailed technical due diligence, end-to-end supply chain mapping and independent quality verification are best suited to mitigate risks related to both regulatory compliance and sustainable module performance. Projects that prioritise upstream QA may benefit from lower degradation rates, higher uptime, and stronger financial performance over the long term.

As Kiwa PI Berlin’s latest findings demonstrate, rigorous cell-level quality assurance delivers measurable technical and financial benefits. By focusing on the cell, owners can better protect their projects from hidden defects and ensure long-term performance. Buyers who implement integrated QA frameworks that combine technical reliability, traceability and policy compliance can differentiate their sourcing strategy, reduce risk exposure and enhance investor confidence. In a time of rapid change, industry leaders will be those who invest the time to understand the nuances of PV cells procurement.

References

[1] Kiwa PI Berlin & Kiwa PVEL, August 2025, ‘The race to PV cell quality and compliance’, www.kiwa.com

[2] Verlinden, P., Young, D. L., Xiong, G., et.al., 2023, ‘Photovoltaic device innovation for a solar future’, Device, 1(1), 100013–100013. https://doi. org/10.1016/j.device.2023.100013

Authors

Don Cowan, director of sales & marketing for North America at Kiwa PI Berlin, has 15 years of experience in the renewable energy industry. Don has held key roles at SMA America and EDF Renewables, spearheading business development initiatives to enhance PV and storage design and equipment support services for utility and C&I projects. Don’s expertise includes advising industry stakeholders on best procurement practices for capex and opex decision-making to ensure the high performance of PV and storage assets, helping accelerate the global energy transition to renewable sources.

Mahyar Mohammadnezhad, principal PV module consultant at Kiwa PI Berlin, has extensive experience in R&D, module technologies, solar energy materials and solar cell innovations. Mahyar has a PhD in energy and materials science, specialising in PV-based research. With over 15 years of experience, Mahyar drives advancements within renowned research groups and R&D departments, making significant contributions to the technical development and design of cutting-edge technologies.