As solar technology advances rapidly, a subtle yet serious threat has emerged – ultraviolet-induced degradation (UVID). This phenomenon refers to the damage sustained by solar modules from prolonged exposure to ultraviolet (UV) radiation. It has been well understood that UV can degrade essential module components, such as encapsulants, backsheets, and sealants, resulting in power loss, safety issues, and early module failure. However, with the introduction of advanced cell technologies that may be more vulnerable to UV stress, stakeholders across the solar value chain—including developers, manufacturers, and investors—must proactively address UVID to safeguard system performance and long-term project bankability.

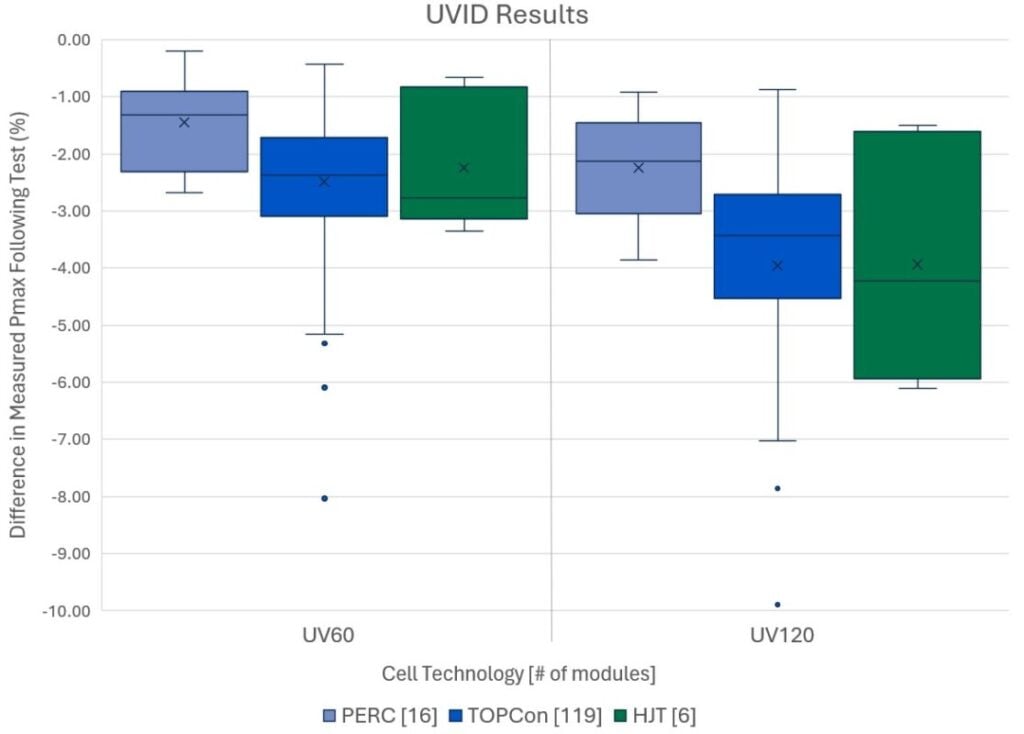

Kiwa PVEL’s UVID testing protocol goes beyond standard IEC/UL certifications, enabling early identification of modules vulnerable to this degradation mechanism. While Tunnel Oxide Passivated Contact (TOPCon) and Heterojunction with Intrinsic Thin Layer (HJT) modules are often advertised for their improved first year and annual degradation rates, our testing over more than a year has revealed that these modules, as well as conventional Passivated Emitter and Rear Cell (PERC) modules have shown significant power loss due to UVID. Although the test duration may not capture the full extent of long-term degradation, it effectively differentiates between UV-susceptible and UV-stable designs, offering valuable insight into long-term module reliability in the outdoor field.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

Inside the 2025 PV Module Reliability Scorecard results

Recent testing has shown that n-type modules, particularly those using TOPCon and HJT technologies, exhibit greater susceptibility to UVID than their p-type counterparts. After UV testing more than 80 bills of materials (BOMs), the median power loss observed was 3.1% for TOPCon and 4.2% for HJT modules, compared to just 2.2% for PERC modules. Multiple failure mechanisms associated with UVID were observed concurrently across different cell types, underscoring the complex nature of this degradation mode.

Encapsulant formulation has a critical role influencing UVID susceptibility. Modules utilising UV-transparent front encapsulants with spectral cut-off wavelengths below 340 nm exhibited higher degradation in UVID testing. In contrast, modules incorporating UV-blocking layers or light down-conversion additives experienced significantly lower power losses, emphasising the importance of appropriate material selection in long-term reliability. However, Kiwa PVEL observed that controlling UVID via the module encapsulant (e.g. UV down conversion encapsulant) was an option mainly utilised by HJT manufacturers and was rarely used in TOPCon BOMs.

Finally, these laboratory observations have been validated through field exposure testing, particularly for TOPCon and HJT BOMs. In Kiwa PVEL’s Field Exposure test in Davis, California, some modules showed up to 8% power loss after one year, with a median power loss of 2%. Given that combined losses from LID and LETID were below 1% for these BOMs, and electroluminescence (EL) imaging revealed a distinct checkerboard degradation pattern, UVID was identified as the primary driver of this performance decline. These findings highlight a real-world reliability challenge for emerging n-type technologies that must be addressed as the industry scales.

Dark storage degradation

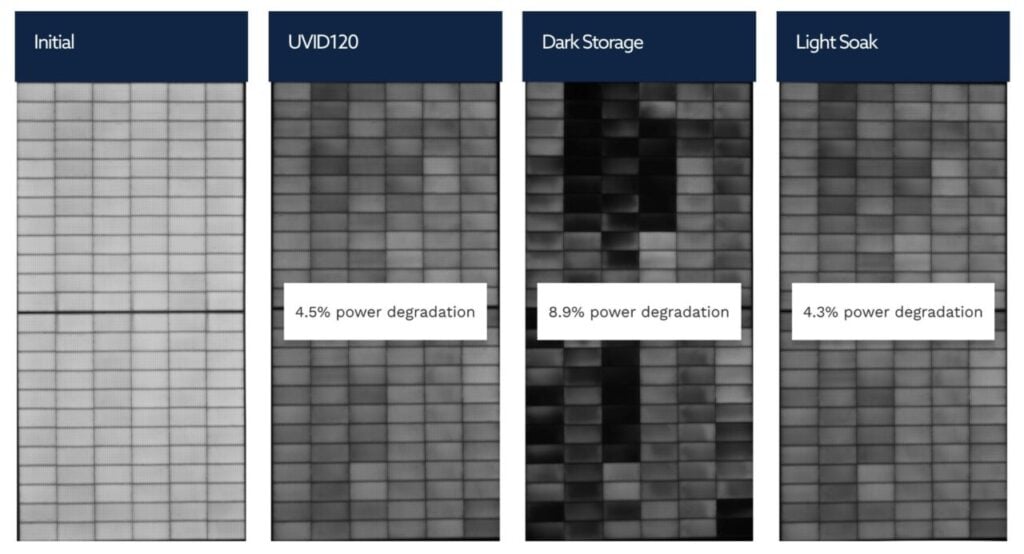

Kiwa PVEL recently identified the signs of metastability in several UVID-stressed and field-exposed modules where significant additional power loss occurred when the modules were stored in the dark after the test’s conclusion. This issue was most notable in UVID-sensitive TOPCon modules, with losses reaching up to 1% per day. An example of this effect is shown below, where the module initially degraded to 4.5% following 120 kWh/m2 of UV exposure, but this degradation nearly doubled after 31 days of storage in the dark room.

A partial recovery of the power degradation was observed by subjecting the module to a short full-spectrum light soak for 0.5 kWh/m2 under open-circuit conditions. However, the residual power degradation remained above 4%, indicating that the recovery is mainly from dark storage metastability and the underlying UV-induced degradation is largely permanent. Further full-spectrum light soaking would not cause additional recovery. This behaviour highlights the complex interaction between UVID and metastability, emphasising the importance of post-test storage conditions in module reliability evaluations.

Conclusion

As the solar industry rapidly transitions to n-type technologies, UVID has emerged as a critical reliability concern. Both laboratory and field testing clearly demonstrate that performance degradation can be substantial – particularly when vulnerable cell architectures are paired with poorly optimised encapsulant materials. Although the mechanisms behind UVID are complex and still under investigation, early identification of at-risk BOMs and informed material selection are already proving vital. For developers, manufacturers, and investors alike, proactively addressing UVID is not merely a technical refinement—it is essential for safeguarding long-term energy output, minimising operational risk, and maintaining confidence in the future of advanced photovoltaic technologies.

Archana Sinha, is PhD, Senior Engineer, and Tristan Erion-Lorico, is VP of Sales and Marketing at Kiwa PVEL.