DSM Advanced Solar has formally launched a new backsheet based on co-extrusion techniques, concluding that traditional backsheet designs are no longer fit for purpose in the longer term.

DSM said the new product, dubbed the Endurance D15, offers an “all purpose” solution to the solar module market while helping lower the levelised cost of electricity (LCOE).

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

DSM bas built the new backsheet on the same co-extrusion technology platform as its existing B series product, using the same polyolefin strong core that the company says is unique to its product range.

The Endurance D15 backsheet is co-extruded without the need for adhesives, which results in a multi-material product that delivers strong resistance to sand abrasion and moisture protection.

Furthermore, the company said it expects the new grade of product to “truly accelerate the introduction of co-extrusion technology in the market”, pointing to it recently receiving the world’s first integrated stress sequence accelerated aging certificate from TÜV SÜD.

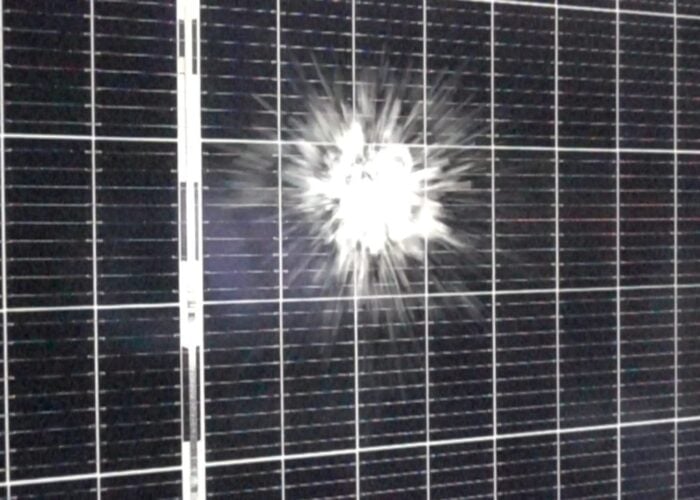

DSM pointed to the latest edition of DuPont’s global PV reliability report which found that around 16% of operating module failures are associated with the product’s backsheet, potentially costing the sector billions of dollars. The report highlighted a rapid increase of cracking in polyvinylidene fluoride backsheets in May this year.

Pascal de Sain, VP at DSM Advanced Solar, said the company was increasingly hearing from customers that traditional backsheet designs had reached their limits, indicating they were “no longer fit for purpose in the longer term”.

“Extreme cost pressure has led to thinner backsheets, made from inferior PET-based materials with less and less fluoropolymer content. But our new Endurance backsheet D15 addresses this challenge by delivering outstanding module protection, based on industry leading technology – affordably,” he said.