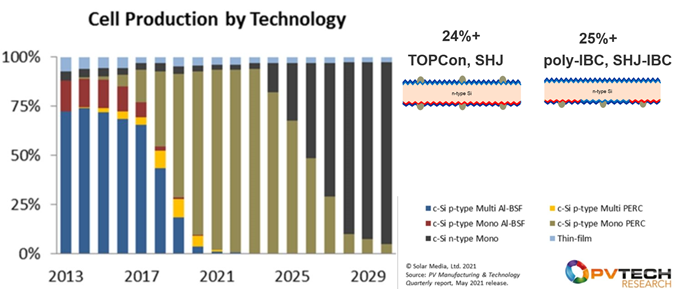

By 2020, Solar PV – with bifacial Passivated Emitter and Rear Cell (PERC) technologies – had been crowned the new king of energy markets, [1] reaching extremely low offers in tenders in the Middle East and North African (MENA) states such as Saudi Arabia, drawing prices as low as US$0.01c/kWh [2] in 2021. As PERC is now coming to its efficiency limits, the question is what next? Who will be “the emperor”? Will there be a fast switch from PERC to n-type technology, as was the case about five years ago for Al-BSF to PERC? PV Tech Research, as depicted in Fig. 1 [3], as almost now the whole PV community, believe so.

Fig. 1: (left) Historical data showing the switch form Al-BSF technology (blue and red bars) to PERC (brown bars) and forecast of a switch to n-type technology (grey bars) in coming years [3]. (right) Schematic cross sections for TOPCon, SHJ and poly-Si- and SHJ-IBC.

But what will be the next mainstream technology? Silicon Heterojunction (SHJ)? TOPCon? A combination of both in an Interdigitated Back Contact (IBC) structure? Tandem cells? The race is on and the muscle-showing announcements are now accelerating. PERC announcements from tier 1 manufacturers on cell and module level advancements have the aim of demonstrating that this technology is still not at its end. N-type technology announcements, however, have the function of showing which way to go in the future.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

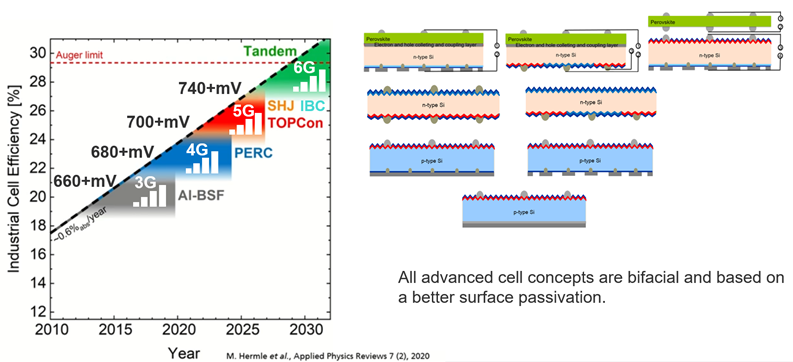

Fig. 2: (left) Efficiency (voltage) improvements and limits of c-Si technologies in the past and coming years with analogy to mobile networks 3G-6G. The graph is adapted from [4]. (right) Schematic cross sections for Al-BSF, mono and bifacial PERC, TOPCon, SHJ, IBC and 2, 3 and 4-terminal tandem configurations.

In theory this is quite simple. Fig. 2 depicts the linear yearly growth of cell efficiencies in industry of about 0.6% absolute, as presented first by Martin Hermle [4]. In 2016 the switch from Al-BSF to PERC was initiated, as Al-BSF technology reached its efficiency limit. This is mostly because of the limited passivation of the rear side by homogeneous Al-BSF, which is depicted in the cross section on the right.

With a dielectric stack (AlOx/SiNx) below the Al-Paste and Al-BSF point contacts, a better rear side passivation can be realised, leading to average voltages of 680mV and maximum of 690mV. Now, to overcome 700mV, passivating contacts with poly-Si in TOPCon or a-Si in SHJ technology have to be applied. Then, in the next step to overcome the Auger or even the Shockley-Queisser limit, tandem structures have to be used. So this linear curve is based in first order on improvements of the voltage by a better passivation with advanced cell structure.

We can compare these technologies to the mobile network and its speed. 3G (Al-BSF) is obsolete and these days the working horse is 4G (PERC), with 5G (passivating contacts) already in place. However, for most applications 4G is still sufficient and the more expensive 5G is not needed. But in a few years we will have 5G everywhere and be preparing the ground even for 6G (tandem).

High efficiency announcements show nothing else than the practical limit of each technology, which is depicted in the graph in Fig. 2. However there is a gap of about 1% absolute between what is possible (with tricks in process flow and in measurements) and what is realistic in production. We have already written in the blog “Future industrial PV technologies: Champion cell announcements versus industrial reality” in 2019, and explained in detail, with which tricks the high efficiency solar cells are fabricated and measured [5]. They very often do not have much to do with their industrial counterpart, even if the technology is named the same. In addition, even the measurements have very often some tricks included (0 Busbar measurements of even active area only, the use conductive and reflective chuck, etcetera).

Table 1 summarises this matter, depicting the record announcements versus average efficiencies in production and available module efficiencies on the market, as well as its potential.

| Technology | Equipment | Announcements of cell efficiency [%] | Average cell efficiency in production [%] | Available module efficiency [%] | Average voltage potential in production [mV] | Average efficiency potential in production [%] |

|---|---|---|---|---|---|---|

| Al-BSF | standard | 20.29 [6] | 19.5 – 20.0 | < 20% | 670 | 20.5 |

| PERC | standard PERC based | 24.06 [10] | 22.5 – 23.5 | 20.2 – 21.1 [7] | 690 | 23.5 |

| TOPCon | standard PERC based | 25.25 [11] | 23.5 – 24.5 | 21.4 [7] | 725 | 24.5 |

| low cost IBC | standard PERC based | 25.04 [12] | 23.5 – 24.5 | 21.3 [7] | 735 | 25.0 |

| low cost SHJ | thin film based | 25.26 [13] | 23.5 – 24.5 | 21.9 [7] | 735 | 25.0 |

| complex SHJ | thin film and electronic industry based | 25.26 [14] | 24.5 – 25.0 | 21.7 [7] | 740 | 25.5 |

| complex IBC | thin film and electronic industry based | 26.1 [15], 26.6 [16] | 25.0 – 25.5 | 22.0 – 22.8 [7] | 740 | 26.0 |

Al-BSF (3G) is fading out of the PV market as it is also monofacial. The average cell efficiencies in production are up to 20%, with voltages around 665mV. The module efficiencies on the market are well below 20%. The king of energy markets, bifacial PERC (4G), has average solar cell efficiencies of about 23% in production. PERC modules on the market are mostly below 21%, but reach up to 21.1% [7] for Trina´s modules. The 23.03% PERC module efficiency announced by Trina recently [8] has not much to do with its standard product and the measured efficiency is even an ‘active area’ measurement only.

While the standard module efficiency is calculated by dividing the electrical output power (Pmpp at STC) by the irradiance captured by the total area of the module (module length multiplied by the module width), the ‘active area module efficiency’ take into account only for the total area of the cells resulting in a significantly higher efficiency value (approaching the cell efficiency) compared to the standard (total area) module efficiency. That means that for the active area module efficiency, the area of the gaps between the cells and the area occupied by bussing ribbons and junction boxes as well as the mandatory gaps between the outer solar cells and the edge of the laminate are not taken into account.

Accordingly, the active area module efficiency is not relevant for the appraisal of benefits of high module efficiency in terms of savings for area related balance of system cost. Recently, measurements in China at CPVT showed even 23.53% [9]. In this article the active area measurement is not mentioned. The 24.06% record PERC cell efficiency reached by LONGi already in 2019 [10] used a selective poly-Si (PERC plus) on the front and also has other features, which are not yet and most likely never will be, implemented in industrial production.

PERC-based technologies like ‘TOPCon’ and ‘PERC-based IBC’ benefit from the PERC cost structure and are therefore low cost as well. The major challenge, as for almost all n-type technologies, is the reduction of Ag-consumption for the metal contacts. TOPCon (5G) cells reach in production an average efficiency of about 23.5%, whereas an efficiency of 25.25% [11] has been demonstrated by JinkoSolar recently.

Here the exact process flow and cell architecture has not been published by Jinko, however, we can assume that most likely a selective poly-Si(B) has been used, which is more complex and not yet ready for industrial mass production, in addition to other non-industrial features. The COO for a standard TOPCon cell is currently about 20-30% higher as for PERC. However its higher efficiency, higher bifaciality, lower degradation and lower temperature coefficient make these modules already attractive not only for roof top applications but for utility-scale solar, as well as for regions which are hot and on systems with high albedo as well.

PERC based IBC (5G) (Jolywood, SPIC, Trina, ValoeCell) has been demonstrated at 25.04% [12] from Trina, is produced at about 24%, having a potential of 25%. At the moment such cells are mostly suited for rooftop PV applications with the reduction of Ag-metallisation, the bifacial version could be also used in utility-scale in the future. For low cost SHJ (5G) (REC, Meyer Burger, Maxwell) an efficiency of 25.26% [13] was demonstrated by Maxwell, whereas complex SHJ (Panasonic, Kaneka) (5G) reached record efficiencies of 25.26% [14] as shown by LONGi. Complex IBC (5G) are produced by Sunpower and LG. 26.1% [15] was demonstrated by ISFH on a POLO structure and 26.6% [16] by Kaneka with SHJ-IBC.

It is now, over the next two to three years, time to switch to low-cost 5G completely. When 6G will come depends mostly on the stability and other challenges for perovskites.

References

[1] https://www.pv-tech.org/iea-solar-the-new-king-of-power-will-break-records-for-decades-to-come/

[2] https://www.spglobal.com/platts/en/market-insights/latest-news/electric-power/042621-saudi-arabia-solar-target-raised-after-seven-projects-added-including-record-low-cost

[3] Solar Media, PV Manufacturing and Technology Quarterly Report, May 2021

[4] M. Hermle et al., Applied Physics Reviews 7 (2), 2020

[5] https://www.pv-tech.org/future-industrial-pv-technologies-champion-cell-announcements-verses-indust/

[6] Ki Hyung Kim et al, Record high efficiency of screen-printed silicon aluminum back surface field solar cell: 20.29%, Japanese Journal of Applied Physics 56(8S2):08MB25, August 2017

[7] https://www.cleanenergyreviews.info/blog/most-efficient-solar-panels

[8] https://www.trinasolar.com/de/resources/newsroom/thu-07012021-1124

[9] https://www.pv-magazine.com/2021/08/20/trina-solar-improves-efficiency-of-210-mm-perc-solar-module-by-0-5/

[10] https://www.pv-tech.org/longi-solar-has-bifacial-mono-perc-solar-cell-world-record-verified-at-24-0/

[11] https://www.pv-tech.org/n-type-cell-efficiency-race-continues-as-jinkosolar-sets-new-record-of-25-25/

[12] https://www.pv-tech.org/trina-solar-takes-n-type-mono-ibc-cell-to-record-25-04-conversion-efficienc/

[13] http://taiyangnews.info/technology/25-26-SHJ-solar-cell-efficiency-for-huasun-energy/

[14] https://www.pv-tech.org/longi-toasts-new-p-type-topcon-and-commercial-heterojunction-cell-efficiency-records/

[15] https://www.nature.com/articles/s41598-019-57310-0

[16] https://www.zmescience.com/ecology/renewable-energy-ecology/solar-cell-close-ideal-limit/