Meca Solar has launched ‘Hyperion-SR,’ which is touted to be the most advanced single row horizontal tracker on the market. Main features are minimum number of piles per MW, self-powered operation, wireless communications, extended slope tolerances and sophisticated optimization.

Problem

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

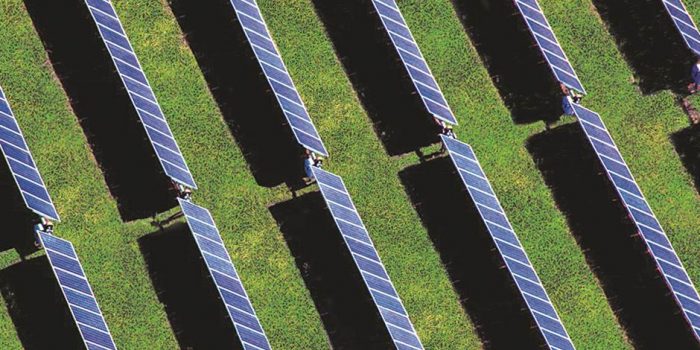

Providing flexibility in the designed of ground mounted PV power plants, while enabling higher land use density to maximize yield are required to reduce the Balance of System Cost (BOS). However, trackers need to provide higher uptime, fast installation and accurate tracking to deliver the highest returns. Increased adoption of 1500VDC technology also requires the longer module rows and trackers that enable this are being demanded.

Solution

The ‘Hyperion-SR tracking system is claimed to increase the PV power plant output up to 27% compared to ground-mounted fixed structure systems while tracker’s dimensions can be extended featuring up to 90 modules per row for 1.5kV DC systems (versions with 80 modules per row for 1kV DC system available) increasing land coverage up to 6%. The self-powered actuator renders the AC power unnecessary. Each row integrates an advanced controller equipped with electrical devices such as UPS, inclinometer and motor current monitor sending its data through a wireless mesh network (zigbee). Raising the system voltage to 1,500 volts allows for 50% longer strings thus reducing the number of strings for the same amount of power which eliminates almost 30% of the related cabling and combiner boxes permitting fewer inverters per project.

Applications

Utility-scale PV power plants

Platform

The weight of the structure has been significantly reduced while the optimized design allows wider rotation angles (+/- 55 degrees). In case of severe weather conditions, the tracker automatically moves in stowing position in less than 3 minutes. The entire tracker can be assembled with fastening devices, therefore on-site welding is not required, reducing workforce cost and mounting time. The ergonomics of the design ensures minimum equipment and installation effort. The Hyperion-SR design can be adapted to client’s needs and the local regulations as per project’s location. Installation training and commission services can be provided at no cost

Availability

Currently available.