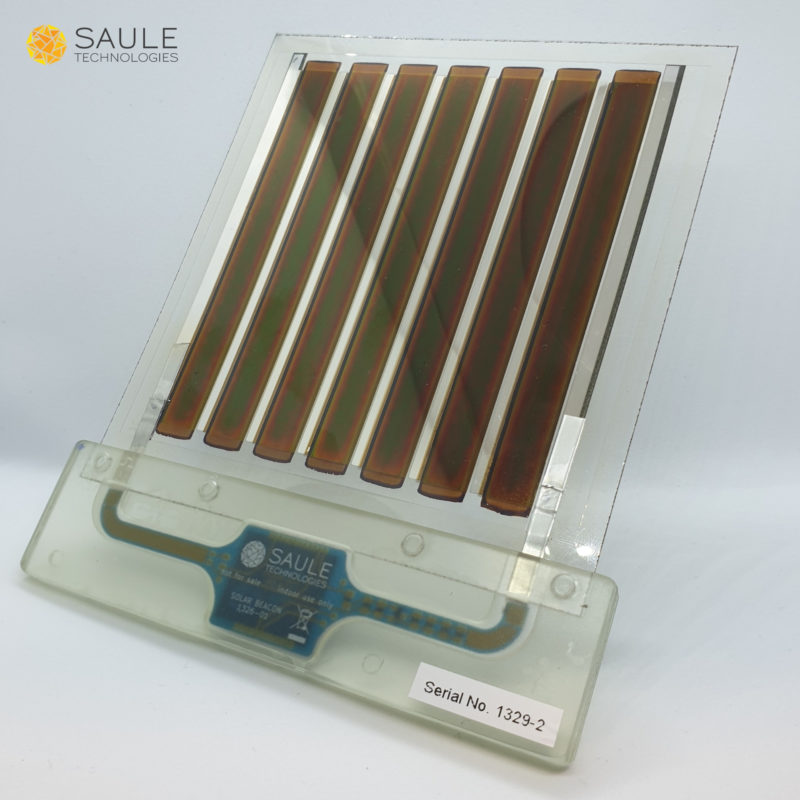

Perovskite-based PV manufacturer, Saule Technologies expects to have its first prototype production line ready in the fourth quarter of 2019, which will produce flexible, lightweight, semi-transparent, single junction solar substrates with 10% conversion efficiencies.

Saule Technologies expects initial production to be 40,000 square meters of single junction perovskite substrates per annum, while plans are being prepared for 2020 to have 200,000 square meters of substrate capacity on an annual basis at its facility in in Wrocław, Poland.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

The prototype production line was said to be printing substrates up to an area of 1 square meter.

Olga Malinkiewicz, Saule Technologies CTO and Founder. “We are incredibly excited with these results especially since Q4 2019 will see the launch of our prototype production line, which will be a modular system of printers targeting the pilot production capability of 40,000 square meters/annum. If we can achieve these results in our detached printer laboratory, then transposing this out of the Lab into the Production Line should see even more progress. Ultimately next year, we plan to expand the line printing capability to 200,000 square meters/annum if the technology transfer goes according to the plan.”

The company said that at the end of March, 2019, its perovskite cells had achieved conversion efficiencies of 17.6%.

“We have seen increased interest from global IoT players – telecommunication companies, sensor manufacturers, and technology giants – as IoT solutions become commercially attractive. Low- and indoor lighting conditions mean higher power conversion efficiency and longer technical life for perovskite solar cells. Our products are targeting to enable fully autonomous IoT devices, eliminating the need to regularly replace batteries” added David Forgacs, Director of Knowledge Management.