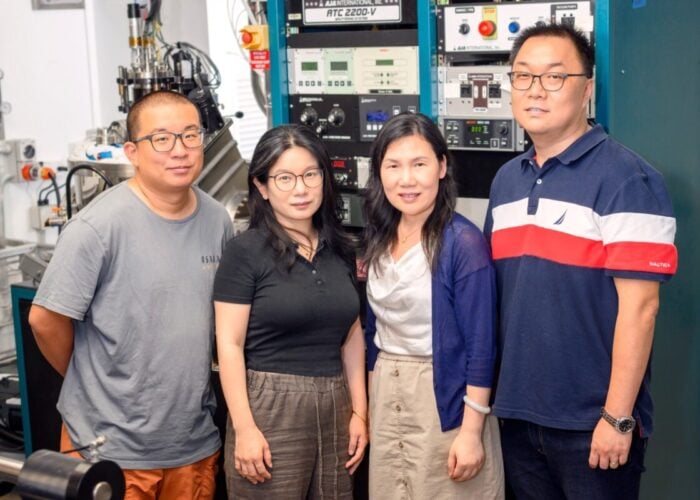

In a joint project lasting five years, six Fraunhofer institutes have published their results regarding next-generation tandem solar cell technology.

Dubbed “MaNiTU”, the Fraunhofer project aimed to identify the most sustainable path to market for tandem solar cells, with perovskite-silicon tandem solar cells in the lead.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

“Perovskite-silicon tandem solar cells made of stable materials and manufactured using scalable production processes are the prerequisite for the next technological leap in the photovoltaic industry,” wrote the report’s authors.

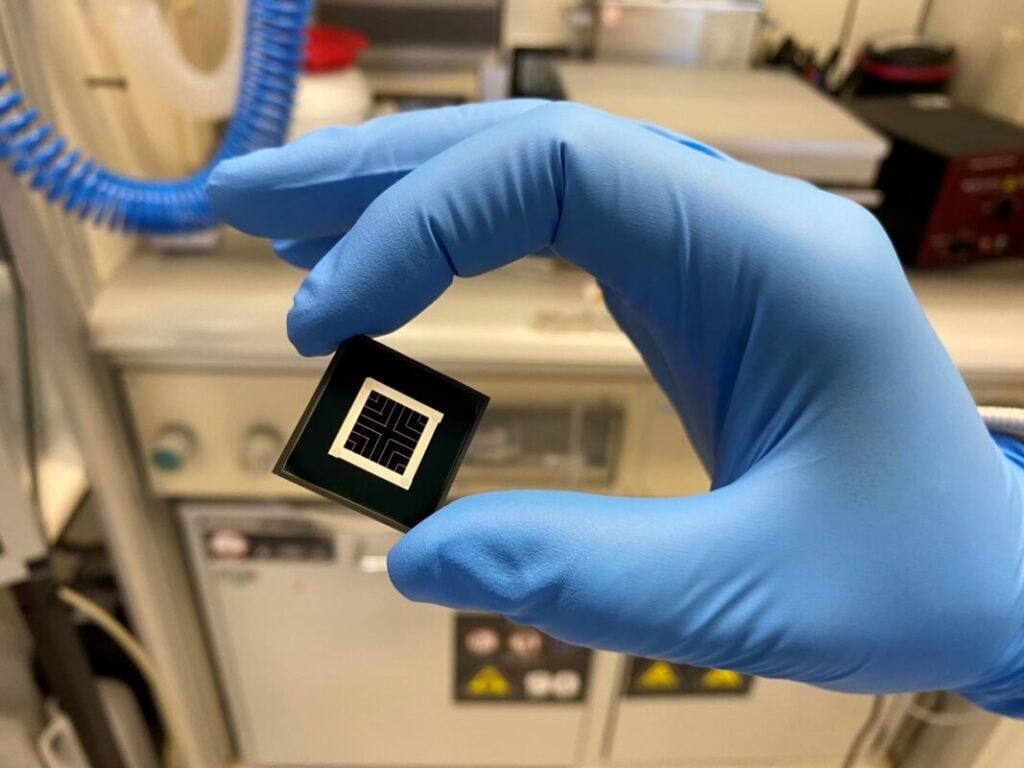

The collaborative project achieved a 31.6% cell efficiency on a 1cm2 area with high-quality perovskite thin films on industrially textured silicon solar cells. This was achieved through a combination of vapour deposition and wet-chemical deposition.

“Close industrial cooperation is the next step in establishing this future technology in Europe,” said Prof. Andreas Bett, institute director at the Fraunhofer Institute for Solar Energy Systems (ISE) and coordinator of the flagship Fraunhofer project.

No suitable solution for lead-free perovskite solar cells

Fraunhofer ISE’s research currently has not found a non-toxic alternative that does not require the use of lead for perovskite compounds to produce tandem solar cells. The research was not able to produce tandem solar cells with sufficient efficiency from any lead-free materials.

With the need to recycle solar panels at the end of their operating lives growing ever more important, the researchers considered the topic of recycling and a closed circular economy in their analyses and managed to develop recycling concepts for perovskites tandem modules.

This includes PV systems with lead perovskites, highlighted Prof. Dr. Peter Dold, director of the Fraunhofer Research Institution for Materials Recycling and Resource Strategies (IWKS). Even though some manufacturers have moved away from the use of lead, it still remains a concern in PV soldering (Premium access).

Researchers also worked towards the development of industry-oriented system components and coating technologies to establish high-performance contact materials for electron and hole contacts in a G12 (210mm) wafer format. However, one of the challenges for perovskite cells is the requirement for low temperatures in the production of the front contact system.

The researchers developed a new process chain in a spatial atomic layer deposition (SALD) hybrid system, consisting of a combination of an ALD and evaporation processes, and supplemented by a final sputter process.

“Our objective is now the development transfer,” explained Dr. Volker Sittinger, head of the Diamond-Based Systems and CleanTech department at Fraunhofer IST. “Together with plant manufacturers and end users, we are working to transfer the new technology from the research lab to the application phase.”

This research is notable considering the results of a separate study, which assessed the characterisation of tandem solar cells, which estimated a practical upper limit of 39.5% efficiency of the cell.

More details regarding the project’s results can be accessed here.