With solar driving the renewables transition in the race to reach net zero as it slowly becomes the cheapest technology to develop a project in, within many regions of the world, the technology needs to adapt to the diverse panorama of locations in which solar PV is being built. Not only that, but also the diversity of weather conditions, as it is no longer uncommon to have projects built in countries or regions with colder conditions such as Canada or Finland, which are at opposite ends of the Atacama desert for example, home to one of the highest irradiation regions in the world.

Because of this, not only modules have to be taken into consideration when considering the diversity of location, but also trackers, in order to optimise a project and give the most economic value out of its over 20-year lifespan.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

The launch of three new products from solar tracker supplier Nextracker – one targeting hail, another uneven terrain and the last around atmospheric changes – can be encompassed in two underlying themes, says Greg Beardsworth, senior director of product marketing at Nextracker.

Understanding the challenges developers are facing with this variety of locations and diverse weather conditions was the first aspect of the launch of the new products.

“Theme one is that solar is making economic sense in more and more places. It’s going everywhere. And that means both the site conditions, and the weather is becoming more diverse. It’s not just the desert Southwest anymore,” says Beardsworth.

As projects are more diversified and happening all across the globe, opening a research and development (R&D) facility in Sorocaba, Brazil, can also give an edge in terms of developing new products that can be more specific not just for Brazil, but for other countries that have similar conditions. One of the research the tracker supplier is currently looking at in the Brazilian R&D facility has to do with agrivoltaics, an area that more and more companies in the solar industry are keen to learn about and implement in solar PV projects.

“We have five people full-time working on studying the productivity of crops with agrivoltaics. How much water you use with or without it, and so forth. But the bottom line is, there’s no question that doing R&D in that country, is helping to accelerate our technologies that are adaptable for that country. There are some very unique soils. As an example, we developed a unique foundation approach that uses a combination of the local soil in Brazil with water and other ingredients to form a soil kind of cement, to create a foundation for the tracker,” says Howard Wenger, president of Nextracker.

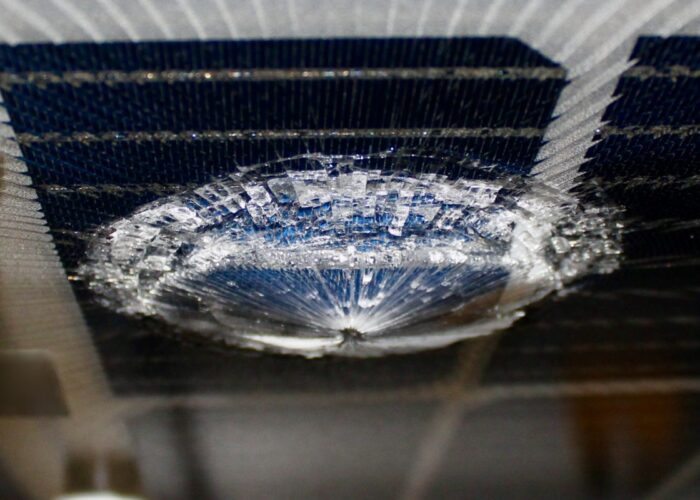

The second theme is around improving on what Nextracker has been doing around hail, terrain and weather, and building around what came before, says Beardsworth, adding: “We’re taking it to the next level, with building on success and track record that we’ve developed so far.” For instance, with NX Horizon Hail Pro, the company brought a more comprehensive structural design to the new version.

The IRA helped accelerate the manufacturing expansion

It’s undeniable that the Inflation Reduction Act (IRA) has been an immense boost for the solar industry, allowing many companies at the upstream level to accelerate their investments towards increasing their manufacturing capacity or building new facilities.

Nextracker is no exception to that, and during the opening day of RE+ 2023 in Las Vegas, opened its latest tracker component manufacturing line in partnership with supply chain solutions company Unimatics. The 15th in the last couple of years, says Wenger.

“We were already mobilising prior to the IRA because of the pandemic and all of the logistics costs, which tripled or steel costs doubled. We were importing 100% of our product three years ago. Prior to the IRA, we started to mobilise here, but the IRA certainly has given us the fuel to go even faster.”

These manufacturing lines have also been spread out across the US, from California to Tennessee, and passing by Texas among others. A critical aspect of that choice is to be as close as possible to where the projects are being developed, adds Wenger. If California and Texas have been the leading markets in the US for the growth of solar PV, it is undeniable that even smaller markets will have a role in the accelerated pace of the US to install solar PV in the coming years, helped by the benefits brought by the IRA.

This is not only true in the US, with 15 manufacturing facilities but also at a global level, with more than 50 facilities, some in Europe – including in Portugal – or in Brazil, the company’s second biggest market after the US and where it opened a research and development facility last year, which aims to harness Brazil’s knowledge of utility-scale solar.

“We want to be local to where the projects are. It is very conceivable, given the scale of our ramp-up of the United States, that we will be exporting certain components made here to projects outside the United States. But right now, we’re racing to serve the need in the United States,” says Wenger.

Many companies in the solar industry, including module manufacturers, are looking into improving the sustainability of their products and making them as environmentally friendly as possible or making sure as many parts can be recycled and given a second life. Trackers are no exception to that, and using steel that is as close to carbon neutrality ensures that.

Beardsworth notes that a benefit from domestically sourcing the steel needed to build the trackers and its components in the US comes from an environmental standpoint.

“The vast majority of the steel going into those torque tubes comes from electric arc furnace steel processing here in the States.” Which is a ten-to-one improvement in terms of carbon emissions, adds Wenger.