As the year comes to a close, there is no doubt that this was the year of consolidation for tunnel oxide passivated contact (TOPCon) technology, which is poised to continue its market dominance for several more years. The n-type technology had already taken the torch from passivated emitter rear contact (PERC) last year, but that technological change also came with its set of quality issues.

Throughout 2025, we’ve seen several research papers and reports from organisations, such as Fraunhofer ISE and others, highlighting performance issues of n-type modules. Even though these problems were already brought to light in 2024, instead of being solved, they seem to have worsened.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

Indeed, Kiwa PVEL’s 2025 Module Reliability Scorecard, which was published in June, registered an 83% module test failure rate this year, up from 66% a year ago.

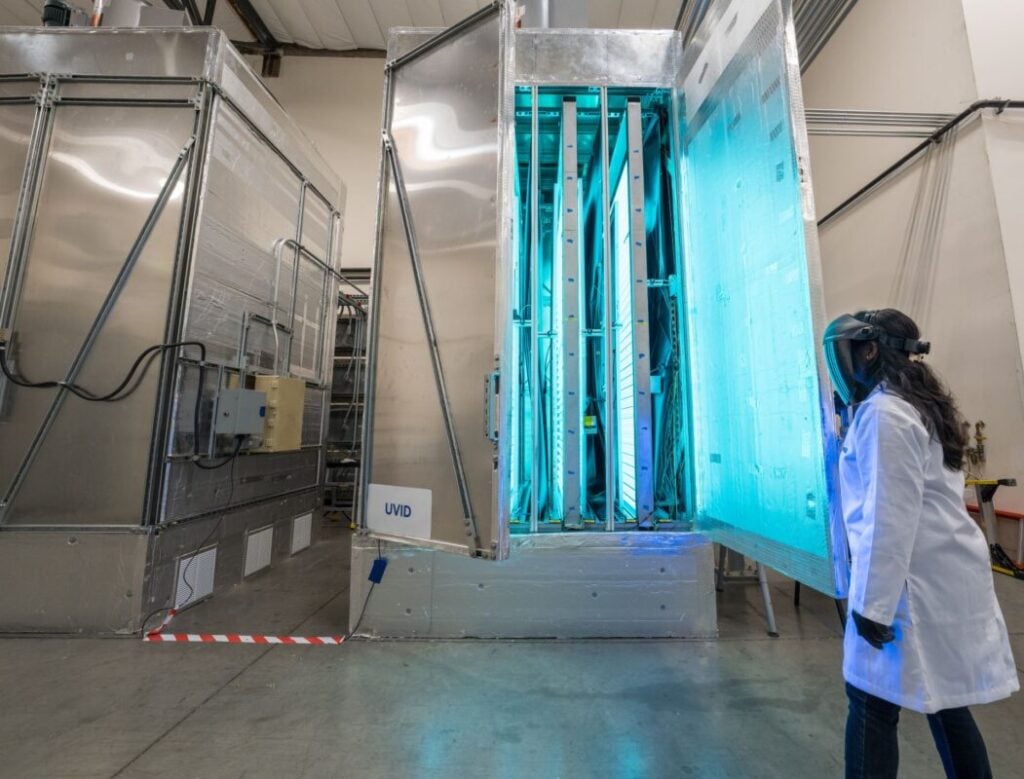

The most common test failures from Kiwa PVEL’s Scorecard were UV-induced degradation (UVID), glass breakage and delamination (subscription required), as was highlighted by Kiwa PVEL’s VP of sales and marketing, Tristan Erion-Lorico, during PV ModuleTech Europe at the beginning of December in Málaga, Spain. The event features presentations on quality issues, such as module breakage and UVID, during its two-day span.

Moreover, delamination defects were recently at the centre of a guest article from Kiwa PVEL, which looked at that problem and how a different bill of materials (BOM) can impact a module’s reliability and testing different BOM can yield different results. Delamination in a module can occur for several reasons, including poor materials choice, usage of thinner encapsulants and/or poor lamination processes.

‘Critical’ degradation in TOPCon modules

As mentioned at the beginning of the article, one of the technologies at the centre of most of these reliability and quality issues is TOPCon. A recent paper by German researchers, including from Fraunhofer ISE, compared 20 TOPCon PV modules in a range of electrical characterisation and accelerated ageing assessments and found “significant reliability issues that remain unresolved”.

According to the paper, despite TOPCon showing resistance to light- and temperature-induced degradation (LeTID) and light-induced degradation (LID), “concerns persist” around the technology’s vulnerability to potential-induced degradation (PID), corrosion and UVID.

In its conclusions, the paper said that degradation from UVID and moisture ingress in particular were “critical”. One of the issues also mentioned in the paper was that current testing standards for commercially available modules is that it generally does not register the power loss from degradation if it does not result in safety issues or a complete failure.

Another study, this time from scientists at the National Renewable Energy Laboratory (NREL)—known now as the National Laboratory of the Rockies—called for enhanced global standards to detect UVID in PV modules after identifying “severe” levels of the problem in operational n-type modules.

The researchers studied passivated emitter rear totally diffused (n-PERT) modules in a 3MW operational PV system that was identified by the owner as underperforming.

Another piece of research, published in August and led by academics at the University of New South Wales (UNSW), highlighted that greater awareness of the type of UV light used to test TOPCon solar cells could result in faster and more efficient assessments of long-term performance.

“UVID is particularly concerning due to the increasing use of UV-transparent encapsulants in photovoltaic modules, which enhances module efficiency but exposes solar cells to UV radiation during operation,” said the UNSW researchers.

However, the conclusions of a Fraunhofer ISE study completed in April are more encouraging, showing that concerns over the performance of TOPCon cells following UV exposure may be exaggerated. According to Fraunhofer’s researchers, common methods used to test for UV degradation can overstate the extent of the issue compared to what is experienced in the field.

The research indicated that UV degradation during testing destabilises modules to such an extent that they significantly lose efficiency during dark storage after UV exposure. Subsequent exposure to sunlight, however, leads to significant recovery, yielding degradation measurements closer to the values actually measured in practice.

In a recent interview with PV Tech Premium, Steven Xuereb, executive director of Kiwa PI Berlin, said that module manufacturers have been making efforts to address the UV degradation issues that have been observed in laboratories.

Xuereb added that one of the challenges around UV degradation is due to the meta-stability of TOPCon cells, which means they degrade when stored in dark conditions but recover when re-exposed to light.

Manufacturers reducing costs

One of the possible causes of the continued trend of quality issues can be associated with the ongoing downturn in the solar manufacturing industry, with the top four major Chinese manufacturers reporting a combined US$1.54 billion in net losses in the first half of the year.

As prices of modules and other components of the supply chain have remained quite low throughout the year, companies have tried to reduce costs in producing modules in order to reduce the losses incurred.

“They’re going to thinner encapsulants,” Erion-Lorico said to PV Tech Premium (subscription required) in June. “They’re probably trying to laminate quicker. The due process changes are made to have higher throughput, to try to limit the amount of money being lost.

“These nine-cent modules, eight-cent modules, the assumption is that those modules are still reliable and they’ll last the warranty period. But we’re seeing that manufacturers have tried to remove materials, remove costs from those modules, to cut their losses, and that presents reliability risks. I think it’s more about that than something inherent in TOPCon or n-type versus p-type.”

In that same interview, Erion-Lorico highlighted the increase in test failures for the mechanical stress sequence (MSS). However, glass breakage is not a new issue across the wider PV lab community and technical advisory community, as it was raised a few years ago already.

In September, technical advisor for PV and battery storage quality assurance, Kiwa PI Berlin, called for greater due diligence in solar PV cells quality and compliance in a guest article on PV Tech.

Finally, Xuereb highlighted the challenges of drawing conclusions due to the limited field data available and separate out TOPCon-specific performance issues that may be occurring from other forms of degradation.

Quality and performance issues have arisen all year round, and was the cover story in the latest edition of our journal, PV Tech Power 44; our subscribers have full access to this and all previous editions of PV Tech Power.